Advantages of Using Flex Rigid PCB Technology

Flex rigid PCB technology is a cutting-edge innovation that is revolutionizing the electronics industry.

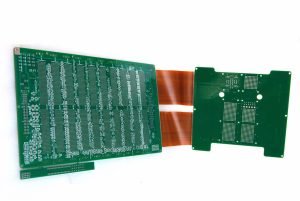

This technology combines the flexibility of a flexible PCB with the rigidity of a rigid PCB, offering a wide range of advantages over traditional PCBs.

In this article, we will explore the benefits of using flex rigid PCB technology and discuss what’s hot and new in this field this month.

One of the key advantages of flex rigid PCB technology is its ability to reduce the overall size and weight of electronic devices.

By eliminating the need for bulky connectors and cables, flex rigid PCBs allow for more compact and lightweight designs.

This is particularly beneficial for portable devices such as smartphones, tablets, and wearable technology, where space and weight are at a premium.

Another advantage of flex rigid PCB technology is its enhanced reliability and durability. Traditional PCBs are prone to failure due to factors such as vibration, shock, and temperature fluctuations. Flex rigid PCBs, on the other hand, are more resistant to these environmental stresses, making them ideal for use in harsh operating conditions. This increased reliability can result in lower maintenance costs and longer product lifespans.

Flex rigid PCB technology also offers improved signal integrity and electrical performance. The flexible sections of the PCB can be used to route high-speed signals with minimal signal loss, while the rigid sections provide stability and support for components. This results in better signal quality, reduced electromagnetic interference, and improved overall performance of the electronic device.

In addition to these advantages, flex rigid PCB technology also offers greater design flexibility. Designers can create complex, three-dimensional shapes that would be impossible with traditional PCBs, allowing for more innovative and creative product designs. This flexibility also enables designers to optimize the layout of components for improved thermal management and signal routing.

Now, let’s take a look at what’s hot and new in flex rigid PCB technology this month. One of the latest trends in the industry is the use of advanced materials and manufacturing techniques to further enhance the performance and reliability of flex rigid PCBs. For example, manufacturers are now using high-performance materials such as polyimide and liquid crystal polymer to improve the flexibility, durability, and thermal properties of flex rigid PCBs.

Another hot trend in flex rigid PCB technology is the integration of advanced features such as embedded components, wireless connectivity, and sensors. These features allow for more compact and intelligent electronic devices that can perform a wide range of functions. For example, a flex rigid PCB with embedded sensors could be used in a wearable fitness tracker to monitor heart rate, steps taken, and calories burned.

In conclusion, flex rigid PCB technology offers a wide range of advantages over traditional PCBs, including reduced size and weight, enhanced reliability and durability, improved signal integrity, and greater design flexibility. The latest trends in the industry focus on using advanced materials and manufacturing techniques to further enhance the performance and functionality of flex rigid PCBs. As this technology continues to evolve, we can expect to see even more innovative and exciting developments in the field of electronics.