Benefits of Flex Rigid PCB Technology

Flex rigid PCB technology has been gaining popularity in recent years due to its numerous benefits and advantages over traditional rigid PCBs. In this article, we will explore some of the key trends to watch out for this month in the world of flex rigid PCB technology.

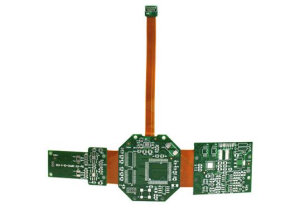

One of the main benefits of flex rigid PCB technology is its ability to reduce the overall size and weight of electronic devices. By combining the flexibility of a flexible PCB with the rigidity of a traditional PCB, manufacturers can create smaller and lighter devices without sacrificing performance or reliability. This is especially important in industries such as aerospace, automotive, and medical devices where space and weight constraints are critical.

Another key benefit of flex rigid PCB technology is its ability to improve reliability and durability. Traditional rigid PCBs are prone to failure due to factors such as vibration, shock, and thermal expansion. Flex rigid PCBs, on the other hand, are more resistant to these factors, making them ideal for use in harsh environments or applications where reliability is paramount.

In addition to their size, weight, and reliability advantages, flex rigid PCBs also offer greater design flexibility. Manufacturers can create complex, three-dimensional designs that would be impossible with traditional rigid PCBs. This allows for more efficient use of space and improved performance in a wide range of applications.

One trend to watch out for this month in the world of flex rigid PCB technology is the increasing use of advanced materials. Manufacturers are constantly developing new materials that offer improved performance, reliability, and durability. By incorporating these materials into their flex rigid PCB designs, manufacturers can create products that are more efficient, reliable, and cost-effective.

Another trend to watch out for is the growing demand for flex rigid PCB technology in emerging industries such as wearable technology, Internet of Things (IoT) devices, and smart home appliances. As these industries continue to grow and evolve, the need for smaller, lighter, and more reliable electronic devices will only increase. Flex rigid PCB technology is well-suited to meet these demands and is expected to play a key role in shaping the future of these industries.

One final trend to watch out for this month is the increasing adoption of automation and robotics in the manufacturing process. As demand for flex rigid PCBs continues to grow, manufacturers are turning to automation and robotics to increase efficiency, reduce costs, and improve quality control. This trend is expected to accelerate in the coming months as manufacturers seek to stay competitive in a rapidly evolving market.

In conclusion, flex rigid PCB technology offers a wide range of benefits and advantages over traditional rigid PCBs. From reducing size and weight to improving reliability and durability, flex rigid PCBs are well-suited for a wide range of applications in industries such as aerospace, automotive, and medical devices. By keeping an eye on the latest trends in the world of flex rigid PCB technology, manufacturers can stay ahead of the curve and continue to innovate and improve their products.