Flex PCB vs Rigid Flex PCB: Understanding the Key Differences

Flex PCBs and rigid flex PCBs are two common types of printed circuit boards used in various electronic devices.

While both serve the same purpose of providing a platform for electronic components to be connected and communicate with each other, there are key differences between the two that are important to understand.

In this article, we will explore the differences between flex PCBs and rigid flex PCBs to help you make an informed decision when choosing the right type of PCB for your electronic device.

Flex PCBs, also known as flexible printed circuit boards, are designed to be flexible and bendable.

They are made of a thin, flexible substrate material such as polyimide or polyester, which allows them to be bent or twisted to fit into tight spaces or irregular shapes. Flex PCBs are ideal for applications where space is limited or where the PCB needs to conform to a specific shape or design.

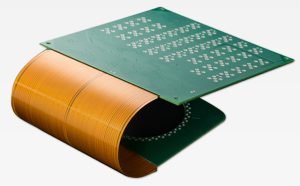

On the other hand, rigid flex PCBs are a combination of both rigid and flexible PCBs.

They consist of multiple layers of rigid PCBs interconnected by flexible PCBs, allowing for a combination of both rigid and flexible sections within the same PCB. Rigid flex PCBs are ideal for applications where both flexibility and rigidity are required, such as in aerospace, medical devices, and military applications.

One of the key differences between flex PCBs and rigid flex PCBs is their flexibility.

Flex PCBs are designed to be highly flexible and bendable, allowing them to be used in applications where flexibility is a key requirement.

Rigid flex PCBs, on the other hand, are less flexible than flex PCBs due to the rigid sections within the PCB.

While rigid flex PCBs offer a combination of both flexibility and rigidity, they are not as flexible as flex PCBs.

Another key difference between flex PCBs and rigid flex PCBs is their construction.Flex PCBs are typically made of a single layer of flexible substrate material, while rigid flex PCBs consist of multiple layers of rigid and flexible materials interconnected to form a single PCB.

This difference in construction allows rigid flex PCBs to offer a higher level of reliability and durability compared to flex PCBs.

In terms of cost, flex PCBs are generally more cost-effective than rigid flex PCBs.

This is because flex PCBs are simpler in construction and require less material compared to rigid flex PCBs.

However, the cost of flex PCBs can vary depending on the complexity of the design and the materials used.

Rigid flex PCBs, on the other hand, are more expensive due to their complex construction and the use of multiple layers of materials.

When choosing between flex PCBs and rigid flex PCBs, it is important to consider the specific requirements of your application.

If flexibility is a key requirement and cost is a concern, flex PCBs may be the best option for your electronic device.

However, if you require a combination of flexibility and rigidity, and reliability is a priority, rigid flex PCBs may be the better choice.

In conclusion, flex PCBs and rigid flex PCBs are two common types of printed circuit boards with key differences in flexibility, construction, and cost. Understanding these differences will help you make an informed decision when choosing the right type of PCB for your electronic device.

Whether you choose flex PCBs or rigid flex PCBs, both types offer unique advantages and can be tailored to meet the specific requirements of your application.