Benefits of Flex PCBs

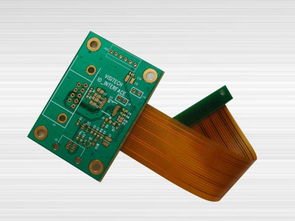

Flex PCBs and rigid flex PCBs are two popular options in the world of printed circuit boards.

Both have their own unique advantages and disadvantages, making it important to carefully consider which option is best for your specific project.

In this article, we will explore the benefits of flex PCBs and how they compare to rigid flex PCBs.

One of the main benefits of flex PCBs is their flexibility.

As the name suggests, flex PCBs are designed to be flexible, allowing them to bend and twist without breaking.

This flexibility makes them ideal for applications where space is limited or where the PCB needs to conform to a specific shape.

Flex PCBs are also lighter and thinner than rigid PCBs, making them a great choice for projects where weight and size are important factors.

Another advantage of flex PCBs is their durability.

Because they are designed to bend and flex, flex PCBs are more resistant to mechanical stress and vibration than rigid PCBs.

This makes them a great choice for applications where the PCB will be subjected to harsh conditions or where reliability is a top priority.

Additionally, flex PCBs have fewer solder joints than rigid PCBs, reducing the risk of failure due to solder fatigue.

Flex PCBs are also more cost-effective than rigid flex PCBs. Because they are made from a single layer of flexible material, flex PCBs are typically less expensive to manufacture than rigid flex PCBs, which require multiple layers of rigid and flexible materials.

This cost savings can make a big difference, especially for projects with tight budgets.

In addition to their flexibility, durability, and cost-effectiveness, flex PCBs also offer greater design flexibility.

Flex PCBs can be designed to fit into tight spaces or to conform to complex shapes, making them a versatile option for a wide range of applications.

They can also be easily integrated with other components, such as sensors or connectors, allowing for more compact and efficient designs.

While flex PCBs offer many benefits, they may not be the best choice for every project.

Rigid flex PCBs, which combine the flexibility of a flex PCB with the rigidity of a rigid PCB, offer some unique advantages of their own.

Rigid flex PCBs are more resistant to heat and moisture than flex PCBs, making them a better choice for applications where temperature and humidity are a concern. They also offer greater reliability and stability than flex PCBs, making them a good choice for high-performance applications.

Ultimately, the decision between flex PCBs and rigid flex PCBs will depend on the specific requirements of your project.

If flexibility, durability, and cost-effectiveness are important factors, flex PCBs may be the best choice for you.

However, if you need greater resistance to heat and moisture, or if you require higher reliability and stability, rigid flex PCBs may be the better option.

In conclusion, both flex PCBs and rigid flex PCBs offer unique benefits that make them suitable for a wide range of applications.

By carefully considering the specific requirements of your project, you can make an informed decision about which type of PCB is best for you.

Whether you choose flex PCBs or rigid flex PCBs, you can rest assured that you are getting a high-quality, reliable product that will meet your needs.