Benefits of Flex PCBs

Flex PCBs and rigid flex PCBs are two popular options in the world of printed circuit boards (PCBs).

Both offer unique advantages and are used in a variety of applications.

In this article, we will explore the benefits of flex PCBs and rigid flex PCBs, and evaluate the performance differences between the two.

Flex PCBs, also known as flexible PCBs, are designed to be flexible and bendable.

They are made of a thin, flexible substrate material such as polyimide or polyester.

Flex PCBs are ideal for applications where space is limited or where the PCB needs to be bent or twisted.

They are commonly used in wearable devices, medical devices, and automotive applications.

One of the main benefits of flex PCBs is their flexibility.

This allows them to be used in applications where traditional rigid PCBs would not be suitable.

Flex PCBs can be bent, twisted, and folded without compromising their performance.

This flexibility also allows for more compact and lightweight designs, making them ideal for portable and space-constrained devices.

Another advantage of flex PCBs is their reliability.

The flexible substrate material used in flex PCBs is highly durable and resistant to mechanical stress. |

This makes flex PCBs less prone to damage from bending or vibration, resulting in a longer lifespan for the PCB and the devices it is used in.

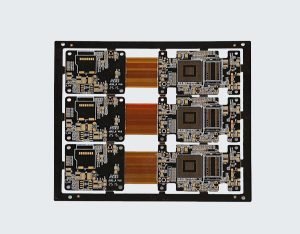

Rigid flex PCBs, on the other hand, combine the benefits of both rigid and flex PCBs.

They consist of a combination of rigid and flexible sections, allowing for more complex and compact designs.

Rigid flex PCBs are commonly used in applications where both flexibility and rigidity are required, such as in aerospace and military applications.

One of the main benefits of rigid flex PCBs is their reliability.

The rigid sections provide stability and support for components, while the flexible sections allow for bending and twisting.

This combination of rigidity and flexibility results in a PCB that is highly reliable and resistant to mechanical stress.

Rigid flex PCBs also offer improved signal integrity compared to flex PCBs.

The rigid sections provide a solid ground plane and reduce signal interference, resulting in better signal quality and reduced electromagnetic interference.

This makes rigid flex PCBs ideal for high-speed and high-frequency applications.

In terms of performance differences, flex PCBs and rigid flex PCBs each have their own strengths and weaknesses.

Flex PCBs are more flexible and lightweight, making them ideal for applications where flexibility is key.

However, they may not offer the same level of signal integrity as rigid flex PCBs.

Rigid flex PCBs, on the other hand, offer improved signal integrity and reliability, making them ideal for high-performance applications.

However, they may be more expensive and complex to manufacture compared to flex PCBs.

In conclusion, both flex PCBs and rigid flex PCBs offer unique benefits and are suitable for different applications.

Flex PCBs are ideal for applications where flexibility and compactness are important, while rigid flex PCBs are better suited for high-performance applications where signal integrity and reliability are critical.

By understanding the performance differences between the two, designers can choose the right type of PCB for their specific application.