Cost Differences Between Flex PCB and Rigid Flex PCB

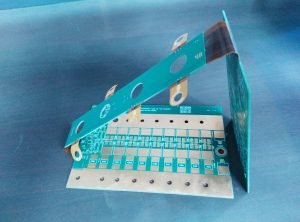

Flex PCBs and rigid flex PCBs are two popular options for electronic manufacturers looking to create flexible and reliable circuit boards.

While both options offer unique benefits, one of the key considerations for manufacturers is the cost difference between the two. In this article, we will explore the cost considerations and budgeting factors associated with choosing between flex PCBs and rigid flex PCBs.

One of the main factors that influence the cost of a PCB is the material used in its construction.

Flex PCBs are typically made from flexible materials such as polyimide or polyester, which are more expensive than the rigid materials used in traditional PCBs.

This difference in material cost can significantly impact the overall cost of a flex PCB compared to a rigid PCB.

Another cost consideration when choosing between flex PCBs and rigid flex PCBs is the complexity of the design.

Flex PCBs are known for their ability to bend and twist, making them ideal for applications where space is limited or where the board needs to conform to a specific shape.

However, this flexibility comes at a cost, as the design and manufacturing process for flex PCBs can be more complex and time-consuming than for rigid PCBs.

This complexity can result in higher manufacturing costs for flex PCBs compared to rigid PCBs.

In addition to material and design complexity, the size of the PCB can also impact the cost.

Flex PCBs are often used in applications where space is limited, such as in wearable devices or medical implants.

In these cases, the smaller size of the flex PCB can result in higher manufacturing costs compared to a larger rigid PCB. Manufacturers must carefully consider the size requirements of their project when budgeting for a flex PCB or rigid flex PCB.

Another cost consideration when choosing between flex PCBs and rigid flex PCBs is the volume of boards needed. Flex PCBs are typically more expensive to manufacture in small quantities compared to rigid PCBs.

This is because the setup costs for flex PCB manufacturing are higher, and the economies of scale are not as favorable for small production runs.

Manufacturers must carefully consider the volume of boards needed for their project when budgeting for a flex PCB or rigid flex PCB.

When budgeting for a flex PCB or rigid flex PCB, manufacturers must also consider the additional costs associated with testing and quality control.

Flex PCBs are more prone to defects and failures due to their flexible nature, which can result in higher testing and quality control costs compared to rigid PCBs.

Manufacturers must factor in these additional costs when budgeting for a flex PCB or rigid flex PCB to ensure the reliability and performance of their electronic devices.

In conclusion, the cost considerations and budgeting factors associated with choosing between flex PCBs and rigid flex PCBs are complex and multifaceted. Manufacturers must carefully weigh the material, design complexity, size, volume, and testing costs when budgeting for a flex PCB or rigid flex PCB.

By carefully considering these factors, manufacturers can make an informed decision that meets their budgetary requirements while ensuring the reliability and performance of their electronic devices.