Benefits of Using Flex PCBs in Electronic Devices

Flex PCBs, or flexible printed circuit boards, have become increasingly popular in the electronics industry due to their numerous benefits.

These flexible circuit boards offer a wide range of advantages over traditional rigid PCBs, making them an ideal choice for many electronic devices.

In this article, we will explore the benefits of using flex PCBs in electronic devices and discuss some of the assembly techniques that can help optimize their performance.

One of the key benefits of using flex PCBs is their flexibility and ability to bend and twist without breaking.

This flexibility allows for greater design freedom, as flex PCBs can be shaped to fit into tight spaces or conform to the contours of a device.

This can be particularly useful in devices with complex or irregular shapes, where rigid PCBs would be difficult or impossible to use.

In addition to their flexibility, flex PCBs are also lightweight and compact, making them ideal for portable electronic devices.

The reduced weight and size of flex PCBs can help to improve the overall performance and efficiency of a device, as well as reduce manufacturing costs. This can be especially important in industries such as aerospace and automotive, where weight and space constraints are critical considerations.

Another benefit of using flex PCBs is their reliability and durability.

Flex PCBs are less prone to mechanical stress and vibration than rigid PCBs, making them more resistant to damage and failure.

This can help to improve the overall lifespan of a device and reduce the need for costly repairs or replacements.

Additionally, flex PCBs are often more resistant to temperature fluctuations and moisture, making them suitable for use in harsh environments.

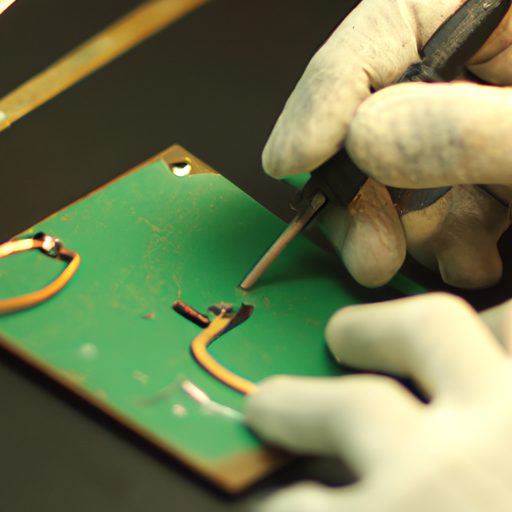

To ensure optimal performance of flex PCBs in electronic devices, it is important to use the right assembly techniques during manufacturing.

One key technique is to use high-quality materials and components that are specifically designed for use with flex PCBs.

This can help to prevent issues such as delamination, cracking, or solder joint failures that can occur when using incompatible materials.

Another important assembly technique is to carefully design the layout of the flex PCB to minimize stress on the board and its components.

This can help to prevent issues such as bending or twisting of the board during operation, which can lead to performance problems or failure.

By carefully planning the layout of the flex PCB and ensuring that components are properly secured, manufacturers can help to optimize the performance and reliability of the board.

In addition to using high-quality materials and designing the layout carefully, it is also important to use proper handling and assembly techniques when working with flex PCBs. This includes using the right tools and equipment, as well as following best practices for soldering and assembly.

By following these guidelines, manufacturers can help to ensure that flex PCBs are assembled correctly and perform optimally in electronic devices.

In conclusion, flex PCBs offer a wide range of benefits for electronic devices, including flexibility, lightweight design, reliability, and durability.

By using the right assembly techniques during manufacturing, manufacturers can help to optimize the performance of flex PCBs and ensure that

they meet the needs of today’s demanding electronic devices. With their numerous advantages, flex PCBs are likely to continue to play a key role in the electronics industry for years to come.