Design Considerations for Flex PCB Assembly

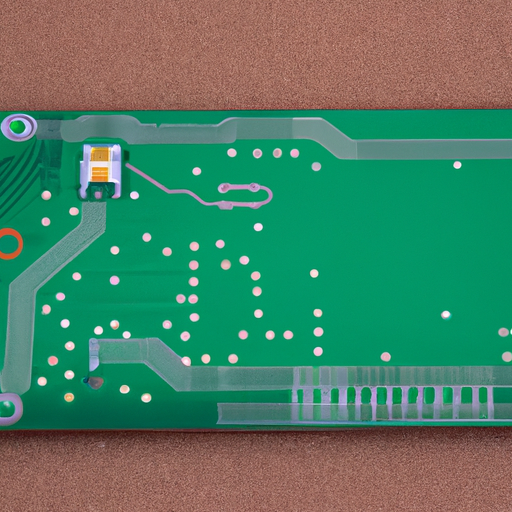

Flex PCB assembly, also known as flexible printed circuit board assembly, is a crucial process in the manufacturing of electronic devices.

Flex PCBs offer numerous advantages over traditional rigid PCBs, including the ability to bend and twist, making them ideal for applications where space is limited or where the circuit board needs to conform to a specific shape.

However, due to their unique properties, flex PCBs require special considerations during the assembly process to ensure reliable circuitry.

One of the key considerations when designing a flex PCB assembly is the choice of materials.

Flex PCBs are typically made of polyimide or polyester substrates, which offer excellent flexibility and durability.

When selecting materials for a flex PCB assembly, it is important to consider factors such as the operating environment, temperature range, and mechanical stress that the circuit board will be subjected to.

Choosing the right materials will help ensure the reliability and longevity of the flex PCB assembly.

Another important consideration for flex PCB assembly is the layout of the circuit board.

Flex PCBs can be designed with multiple layers, allowing for complex circuitry in a compact form factor.

However, the layout of the circuit board must take into account the flexibility of the substrate and the bending radius of the board.

Careful consideration should be given to the placement of components, traces, and vias to ensure that they can withstand the bending and

flexing of the circuit board without compromising the integrity of the connections.

In addition to material selection and circuit board layout, proper handling and assembly techniques are essential for ensuring the reliability of a flex PCB assembly.

Flex PCBs are more delicate than rigid PCBs and can be easily damaged if not handled properly.

During the assembly process, it is important to use gentle handling techniques and avoid excessive bending or twisting of the circuit board.

Components should be soldered carefully to prevent damage to the flexible substrate, and any excess stress on the board should be minimized to

prevent cracking or delamination.

Furthermore, thermal management is a critical consideration for flex PCB assembly.

Flex PCBs are more sensitive to temperature variations than rigid PCBs, and excessive heat can cause the substrate to deform or delaminate.

Proper thermal management techniques, such as using low-temperature soldering processes and ensuring adequate airflow during soldering,

are essential for preventing damage to the flex PCB assembly.

Additionally, thermal stress analysis should be conducted to identify potential hot spots on the circuit board and mitigate any issues that may arise during operation.

In conclusion, designing a reliable flex PCB assembly requires careful consideration of materials, layout, handling, and thermal management.

By following best practices for flex PCB assembly, such as selecting the right materials, designing a suitable layout, using proper handling techniques,

and implementing effective thermal management strategies, manufacturers can ensure the longevity and reliability of their electronic devices.

Flex PCBs offer unique advantages for applications where flexibility and space-saving are essential, and by following these best practices, manufacturers can harness the full potential of flex PCB technology for their electronic products.