Advancements in Rigid Flex Technology

Rigid flex technology has been a game-changer in the world of electronics manufacturing, offering a unique combination of flexibility and durability that traditional rigid PCBs cannot match. As technology continues to evolve at a rapid pace, the future of rigid flex technology looks brighter than ever.

In this article, we will explore some of the advancements that are shaping the future of rigid flex technology and the potential impact they may have on various industries.

One of the key advancements in rigid flex technology is the development of new materials that offer improved performance and reliability.

Traditional rigid flex materials have limitations in terms of flexibility and durability, but recent innovations have led to the creation of materials that can withstand harsh environments and extreme conditions. These new materials are not only more flexible but also more resistant to heat, moisture, and other environmental factors, making them ideal for a wide range of applications.

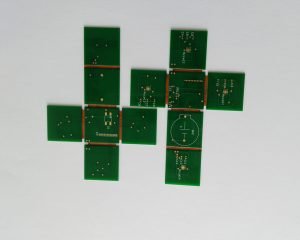

Another important advancement in rigid flex technology is the miniaturization of components. As electronic devices become smaller and more compact, the demand for smaller and more flexible PCBs has increased. Rigid flex technology allows for the integration of multiple components into a single board, reducing the overall size of the device and improving its performance. This miniaturization trend is expected to continue in the future, with even smaller and more complex devices becoming a reality.

Advancements in manufacturing processes have also played a significant role in shaping the future of rigid flex technology.

New techniques such as laser drilling and 3D printing have made it possible to create intricate and complex designs that were previously impossible with traditional manufacturing methods. These advancements have not only improved the quality and reliability of rigid flex boards but have also reduced production costs and lead times, making them more accessible to a wider range of industries.

The integration of advanced technologies such as artificial intelligence and machine learning is another exciting development in the world of rigid flex technology. These technologies have the potential to revolutionize the design and manufacturing process, allowing for faster and more efficient production of rigid flex boards. AI algorithms can analyze complex design requirements and optimize the layout of components on the board, leading to improved performance and reliability. Machine learning algorithms can also predict potential defects and failures, allowing for proactive maintenance and troubleshooting.

The future of rigid flex technology is not without its challenges, however. As devices become more complex and interconnected, the demand for higher data transfer speeds and greater bandwidth is increasing. This requires the development of new materials and manufacturing processes that can support these requirements. Additionally, the need for improved reliability and durability in harsh environments poses a significant challenge for manufacturers.

Despite these challenges, the future of rigid flex technology looks promising. With continued advancements in materials, manufacturing processes, and design techniques, rigid flex boards are poised to become even more versatile and reliable. From consumer electronics to aerospace and defense, rigid flex technology is set to revolutionize the way we think about electronic devices. As we look ahead to the future, it is clear that rigid flex technology will play a crucial role in shaping the next generation of electronic devices.