Advancements in Flex Rigid PCB Manufacturing Processes

Flex rigid PCB technology has been making significant advancements in recent years, with new developments constantly being introduced to improve the manufacturing processes. This month, there are several exciting developments in flex rigid PCB technology that are worth noting.

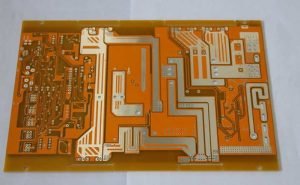

One of the key advancements in flex rigid PCB manufacturing processes is the use of advanced materials.

Manufacturers are now utilizing high-performance materials that offer improved flexibility, durability, and reliability.

These materials are essential for creating PCBs that can withstand the rigors of various applications, including those in harsh environments.

In addition to advanced materials, manufacturers are also incorporating innovative design techniques to enhance the performance of flex rigid PCBs.

By utilizing advanced design software and tools, engineers can create PCB layouts that optimize signal integrity, reduce electromagnetic interference, and improve overall functionality. These design techniques are crucial for ensuring that flex rigid PCBs meet the stringent requirements of modern electronic devices.

Another exciting development in flex rigid PCB technology is the use of advanced manufacturing processes. Manufacturers are now employing state-of-the-art equipment and techniques to produce PCBs with higher precision and efficiency. These advanced manufacturing processes enable manufacturers to create complex PCB designs with tight tolerances and intricate features, making them ideal for a wide range of applications.

Furthermore, advancements in flex rigid PCB technology have also led to improvements in assembly and testing processes. Manufacturers are now able to streamline the assembly process by using automated equipment and robotic systems, which can significantly reduce production time and costs. Additionally, advanced testing techniques, such as automated optical inspection and X-ray inspection, ensure that flex rigid PCBs meet the highest quality standards before they are shipped to customers.

Overall, the advancements in flex rigid PCB technology are driving innovation in the electronics industry, enabling manufacturers to create more reliable and high-performance electronic devices. With the use of advanced materials, design techniques, manufacturing processes, and testing methods, flex rigid PCBs are becoming increasingly versatile and adaptable to a wide range of applications.

As technology continues to evolve, we can expect to see even more exciting developments in flex rigid PCB technology in the future.

Manufacturers are constantly pushing the boundaries of what is possible, and the result is a new generation of flex rigid PCBs that are smaller,

lighter, and more powerful than ever before.

In conclusion, the advancements in flex rigid PCB technology are revolutionizing the electronics industry, paving the way for new and innovative electronic devices. With the use of advanced materials, design techniques, manufacturing processes, and testing methods, flex rigid PCBs are becoming increasingly reliable and high-performance. As we look to the future, we can expect to see even more exciting developments in flex rigid PCB technology that will continue to shape the electronics industry for years to come.