Benefits of Using Rigid-Flex Assembly Technology for Enhanced Performance and Durability

In the world of electronics manufacturing, the demand for smaller, lighter, and more durable devices continues to grow.

As a result, engineers and designers are constantly seeking innovative solutions to meet these evolving requirements.

One technology that has gained popularity in recent years is rigid-flex assembly technology, which offers a unique combination of flexibility and rigidity that can enhance the performance and durability of electronic devices.

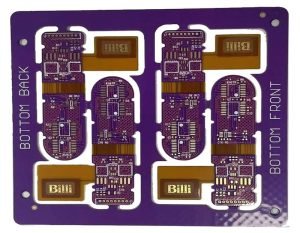

Rigid-flex assembly technology involves combining rigid circuit boards with flexible circuitry to create a single, integrated solution.

This approach allows for greater design flexibility, as engineers can create complex, three-dimensional shapes that would be difficult or impossible to achieve with traditional rigid PCBs.

By eliminating the need for connectors and cables, rigid-flex assemblies can also reduce the overall size and weight of a device, making them ideal for applications where space is at a premium.

One of the key benefits of using rigid-flex assembly technology is improved reliability.

Traditional PCBs are prone to failure due to factors such as vibration, shock, and thermal cycling.

By integrating rigid and flexible elements into a single assembly, engineers can create a more robust design that is better able to withstand these environmental stresses.

This can result in longer product lifetimes and reduced maintenance costs, making rigid-flex assemblies an attractive option for mission-critical applications.

Another advantage of rigid-flex assembly technology is improved signal integrity.

In traditional PCBs, signal paths are often routed through multiple layers of copper, which can lead to signal degradation and interference.

By using rigid-flex assemblies, engineers can create shorter, more direct signal paths that minimize signal loss and improve overall performance.

This can be especially important in high-speed applications where signal integrity is critical to the operation of the device.

In addition to reliability and signal integrity, rigid-flex assembly technology offers a number of other benefits.

For example, the elimination of connectors and cables can reduce assembly time and labor costs, making rigid-flex assemblies a cost-effective solution for high-volume production.

The ability to create complex, three-dimensional shapes also opens up new possibilities for product design, allowing engineers to create smaller, lighter, and more innovative devices.

Overall, rigid-flex assembly technology offers a number of advantages for engineers and designers looking to enhance the performance and durability of their electronic devices.

By combining the flexibility of flexible circuitry with the rigidity of traditional PCBs, engineers can create robust, reliable designs that are well-suited to

a wide range of applications. Whether you are designing a consumer electronics device, a medical instrument, or an aerospace system, rigid-flex

assembly technology can help you achieve your performance and durability goals.