Benefits of Using Rigid-Flex PCBs in Medical Devices

Medical devices play a crucial role in the healthcare industry, providing essential diagnostic and treatment capabilities to patients around the world.

As technology continues to advance, the demand for more sophisticated and reliable medical devices has increased.

One key component that plays a significant role in the performance of these devices is the printed circuit board (PCB).

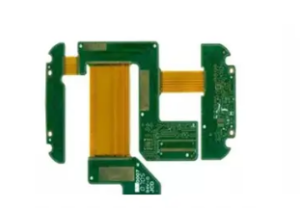

In recent years, rigid-flex PCB solutions have emerged as a popular choice for medical device manufacturers looking to enhance the performance and reliability of their products.

Rigid-flex PCBs offer a number of benefits that make them well-suited for use in medical devices.

One of the primary advantages of rigid-flex PCBs is their ability to reduce the overall size and weight of a device.

By combining rigid and flexible PCB materials into a single design, manufacturers can create more compact and lightweight devices that are easier to handle and transport.

This is particularly important in the medical field, where space is often limited and portability is a key consideration.

In addition to their compact size, rigid-flex PCBs also offer improved reliability compared to traditional PCBs.

The flexible portions of the PCB are less prone to mechanical stress and vibration, reducing the risk of component failure and extending the lifespan of the device.

This increased reliability is especially important in medical devices, where malfunctions can have serious consequences for patients.

Another benefit of using rigid-flex PCBs in medical devices is their ability to support complex and intricate designs.

The flexible portions of the PCB can be bent and folded to fit into tight spaces or conform to the shape of the device, allowing for greater design flexibility and customization.

This is particularly useful in devices such as implantable medical devices, where space is limited and the PCB must be able to conform to the contours of the body.

Furthermore, rigid-flex PCBs offer improved signal integrity and reduced electromagnetic interference (EMI) compared to traditional PCBs.

The flexible portions of the PCB act as a shield, protecting sensitive components from external interference and ensuring that signals are transmitted accurately and reliably.

This is critical in medical devices, where precise communication between components is essential for proper functioning.

Overall, the benefits of using rigid-flex PCBs in medical devices are clear.

These advanced PCB solutions offer a combination of compact size, improved reliability, design flexibility, and signal integrity that make them an ideal choice for manufacturers looking to enhance the performance of their products. By incorporating rigid-flex PCBs into their designs, medical device manufacturers can create more reliable, efficient, and innovative devices that meet the evolving needs of healthcare providers and patients alike.