Benefits of Using Rigid Flex PCBs for Enhanced Durability and Reliability

In the world of electronics, durability and reliability are two key factors that can make or break a product.

Whether it’s a consumer device or a critical component in a larger system, the ability of a circuit board to withstand the rigors of daily use and maintain consistent performance over time is crucial. This is where rigid flex PCBs come into play, offering a unique combination of flexibility and rigidity that can enhance the durability and reliability of electronic devices.

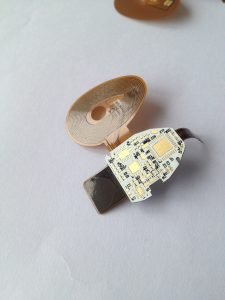

Rigid flex PCBs are a type of circuit board that combines the benefits of both rigid and flexible PCBs.

They consist of multiple layers of flexible circuitry that are interconnected by rigid sections, creating a board that can bend and flex to fit into tight spaces while still providing the structural integrity and stability of a traditional rigid PCB. This hybrid design allows for greater design flexibility and reliability, making rigid flex PCBs an ideal choice for applications where durability is a top priority.

One of the key benefits of using rigid flex PCBs is their ability to withstand mechanical stress and vibration.

Traditional rigid PCBs are prone to cracking and breaking when subjected to repeated bending or twisting, which can lead to premature failure of the circuitry. In contrast, the flexible sections of a rigid flex PCB can absorb and distribute mechanical stress more effectively, reducing the risk of damage and extending the lifespan of the board. This makes rigid flex PCBs an excellent choice for applications that require frequent movement or exposure to harsh environmental conditions.

Another advantage of rigid flex PCBs is their ability to reduce the number of interconnects and solder joints in a circuit.

Traditional PCBs rely on multiple connectors and soldered connections to link different components together, increasing the risk of signal interference, electrical noise, and mechanical failure. By integrating flexible circuitry into the design, rigid flex PCBs can eliminate the need for many of these interconnects, creating a more streamlined and reliable circuit layout. This not only improves the overall performance of the board but also reduces the likelihood of failure due to poor connections or solder joints.

In addition to their durability and reliability, rigid flex PCBs offer a number of other benefits that can help enhance the performance and longevity of electronic devices. For example, the flexible sections of a rigid flex PCB can be used to create complex three-dimensional shapes and configurations that would be impossible with a traditional rigid PCB. This allows for more compact and efficient designs, reducing the overall size and weight of the device while improving its functionality and usability.

Furthermore, rigid flex PCBs are also more resistant to temperature fluctuations and moisture exposure than traditional PCBs.

The flexible circuitry used in rigid flex PCBs is typically made from materials that are more resistant to heat, cold, and humidity, making them ideal for applications that require reliable performance in extreme environments. This can be particularly important in industries such as aerospace, automotive, and medical devices, where electronic components must operate flawlessly under challenging conditions.

Overall, the use of rigid flex PCBs can provide significant benefits in terms of durability and reliability, making them an excellent choice for a wide range of electronic applications. By combining the flexibility of a flexible PCB with the stability of a rigid PCB, these innovative circuit boards offer a unique solution for designers looking to create high-performance, long-lasting electronic devices. Whether it’s improving mechanical strength, reducing interconnects, or enhancing environmental resistance, rigid flex PCBs have the potential to take electronic design to the next level.