Benefits of Using Electric Flex-Rigid PCB Design

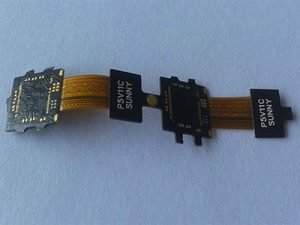

Electric Flex-Rigid PCB

In the world of electronics, the design of printed circuit boards (PCBs) plays a crucial role in the functionality and performance of electronic devices.

One innovative approach to PCB design that has gained popularity in recent years is the use of electric flex-rigid PCBs.

These PCBs offer a number of benefits over traditional rigid PCBs, making them an attractive option for a wide range of applications.

One of the key benefits of using electric flex-rigid PCB design is the flexibility it offers in terms of form factor.

Traditional rigid PCBs are limited in their ability to conform to non-linear shapes or fit into tight spaces.

Electric flex-rigid PCBs, on the other hand, can be bent or folded to fit into compact or irregularly shaped enclosures, allowing for more efficient use of space in electronic devices.

Another advantage of electric flex-rigid PCB design is the increased reliability it provides.

Traditional rigid PCBs are prone to failure due to factors such as vibration, shock, and thermal expansion. Electric flex-rigid PCBs, with their combination of flexible and rigid sections, are better able to withstand these environmental stresses, resulting in a more robust and reliable electronic system.

In addition to improved reliability, electric flex-rigid PCB design also offers enhanced signal integrity.

The flexible sections of the PCB can be used to route high-speed signals with minimal impedance, reducing signal loss and improving overall performance.

This makes electric flex-rigid PCBs ideal for applications that require high-speed data transmission, such as telecommunications, networking, and consumer electronics.

Furthermore, electric flex-rigid PCB design can help to simplify the assembly process for electronic devices.

By integrating multiple PCBs into a single flex-rigid design, manufacturers can reduce the number of interconnects and solder joints, leading to a more streamlined and cost-effective assembly process. This can result in faster production times and lower manufacturing costs, making electric flex-rigid PCBs a practical choice for mass production.

Another benefit of using electric flex-rigid PCB design is the potential for increased design flexibility.

With traditional rigid PCBs, designers are limited in their ability to create complex layouts or incorporate multiple layers of circuitry. Electric flex-rigid PCBs,

with their combination of flexible and rigid sections, offer greater design freedom, allowing for more creative and innovative solutions to electronic design challenges.

Overall, the benefits of electric flex-rigid PCB design make it a compelling choice for a wide range of electronic applications.

From improved reliability and signal integrity to simplified assembly processes and increased design flexibility, electric flex-rigid PCBs offer a number of advantages over traditional rigid PCBs. As technology continues to evolve and demand for smaller, more powerful electronic devices grows, electric flex-rigid PCB design is likely to become an increasingly important tool for electronics designers and manufacturers.