Streamlining the Design Process for Rigid Flex PCBs

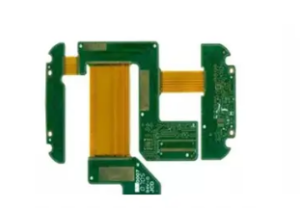

Rigid flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are ideal for applications where space is limited, and where the board needs to be able to bend or flex without breaking.

However, manufacturing rigid flex PCBs can be a complex and time-consuming process. In order to streamline the design process for rigid flex PCBs,

it is important to implement efficient manufacturing processes.

One of the key steps in the manufacturing process of rigid flex PCBs is the design phase.

Designing a rigid flex PCB requires careful consideration of both the rigid and flexible portions of the board, as well as the connections between them.

It is important to work closely with the PCB manufacturer during the design phase to ensure that the design is optimized for manufacturing.

By involving the manufacturer early in the design process, potential issues can be identified and addressed before production begins.

Once the design phase is complete, the next step in the manufacturing process is to create the PCB layout.

This involves placing the components on the board and routing the traces to connect them.

When designing a rigid flex PCB, it is important to consider the unique challenges that come with combining rigid and flexible materials.

For example, the flexible portions of the board may require special routing techniques to prevent damage during bending or flexing.

By working closely with the manufacturer during the layout phase, these challenges can be addressed early on, saving time and reducing the risk of errors.

After the PCB layout is complete, the next step in the manufacturing process is to fabricate the board.

This involves etching the copper traces onto the board, drilling holes for the components, and laminating the rigid and flexible layers together.

In order to streamline the fabrication process, it is important to work with a manufacturer that has experience in producing rigid flex PCBs.

By choosing a manufacturer with the right expertise and equipment, you can ensure that your boards are fabricated to the highest quality standards.

Once the boards have been fabricated, the final step in the manufacturing process is to assemble the components onto the board.

This involves soldering the components onto the PCB and testing the board to ensure that it functions correctly.

In order to streamline the assembly process, it is important to work with a manufacturer that has experience in assembling rigid flex PCBs.

By choosing a manufacturer with the right expertise and equipment, you can ensure that your boards are assembled quickly and accurately.

In conclusion, efficient manufacturing processes are essential for streamlining the design process for rigid flex PCBs.

By working closely with the manufacturer during the design, layout, fabrication, and assembly phases, you can ensure that your boards are produced to the highest quality standards. By choosing a manufacturer with the right expertise and equipment, you can save time and reduce the risk of errors during the manufacturing process. With the right approach, you can create high-quality rigid flex PCBs that meet the unique requirements of your application.