Ease of Integration: Simplifying Smart Device Design with Rigid-Flex PCBs

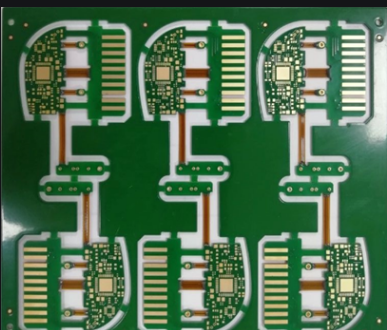

The functionality of modern smart devices relies heavily on the seamless integration of various components, such as sensors, processors, and communication modules. Rigid-flex printed circuit boards (PCBs) have become a cornerstone of this integration process, offering a versatile and efficient solution for connecting and organizing complex circuitry. Their unique design, which combines rigid and flexible sections, enables easier integration of components, making rigid-flex PCBs an essential tool for developing advanced smart devices.

One of the primary advantages of rigid-flex PCBs is their ability to accommodate a wide range of components in a compact and organized layout.

Unlike traditional rigid PCBs, which often require additional connectors and wiring to link different parts of the device, rigid-flex PCBs integrate these connections into a single, unified board. This eliminates the need for bulky connectors and reduces the overall size of the device, allowing for more efficient use of space. For example, in smartphones, rigid-flex PCBs enable the integration of cameras, fingerprint sensors, and display connectors into a single board, simplifying the design and assembly process.

The flexibility of rigid-flex PCBs also makes them ideal for integrating sensors, which are a critical component of many smart devices.

Sensors are often placed in locations that require the PCB to bend or conform to specific shapes, such as in wearable devices or medical equipment.

Rigid-flex PCBs can be designed to fit these unique form factors, ensuring that sensors are securely connected and positioned for optimal performance.

This is particularly important in applications like fitness trackers, where heart rate sensors and accelerometers must maintain consistent contact with the user’s body.

In addition to simplifying the physical integration of components, rigid-flex PCBs enhance electrical performance by reducing signal loss and interference.

The seamless connections between rigid and flexible sections minimize the need for solder joints and connectors, which can introduce resistance and signal degradation. This is especially beneficial for high-frequency applications, such as 5G-enabled devices, where maintaining signal integrity is crucial.

By providing a more reliable and efficient pathway for electrical signals, rigid-flex PCBs ensure that smart devices operate at peak performance.

The ease of integration offered by rigid-flex PCBs also extends to the assembly process.

With fewer components to connect and assemble, manufacturers can streamline production, reducing labor costs and minimizing the risk of errors.

This is particularly advantageous in high-volume industries like consumer electronics, where efficiency and cost-effectiveness are critical. Additionally, the simplified assembly process allows for faster prototyping and iteration, enabling manufacturers to bring new products to market more quickly.

Furthermore, rigid-flex PCBs support the integration of advanced technologies, such as Internet of Things (IoT) modules and artificial intelligence (AI) processors. These technologies often require complex circuitry and high-density interconnects, which can be challenging to implement with traditional PCBs. Rigid-flex PCBs provide the necessary flexibility and performance to accommodate these advanced components, enabling the development of smarter and more connected devices.

In conclusion, the ease of integration provided by rigid-flex PCBs is a key factor in the design and functionality of modern smart devices.

By simplifying the connection of sensors and other components, rigid-flex PCBs enable more compact, efficient, and reliable designs.

As the demand for advanced smart devices continues to grow, rigid-flex PCBs will remain an indispensable technology, driving innovation and shaping the future of electronics.