Advancements in Rigid-FlexibleCircuit Board Manufacturing

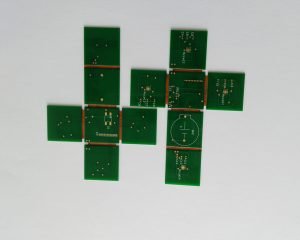

In the world of electronics manufacturing, rigid-flexible circuit boards have become increasingly popular due to their ability to combine the benefits of both rigid and flexible circuit boards. These innovative boards are made up of both rigid and flexible materials, allowing for greater design flexibility and improved reliability. As technology continues to advance, so too does the manufacturing process for rigid-flexible circuit boards.

One of the key advancements in rigid-flexible circuit board manufacturing is the use of laser technology. Laser cutting and drilling have become essential processes in the production of these boards, as they allow for precise and intricate designs to be created with minimal waste. By using lasers, manufacturers can achieve higher levels of accuracy and consistency, resulting in circuit boards that are more reliable and efficient.

Another important development in rigid-flexible circuit board manufacturing is the use of advanced materials. Traditional rigid circuit boards are typically made of fiberglass and copper, while flexible circuit boards are made of polyimide or polyester. However, manufacturers are now experimenting with new materials such as liquid crystal polymer (LCP) and polyether ether ketone (PEEK) to create boards that are even more durable and flexible.

In addition to laser technology and advanced materials, automation has also played a significant role in the evolution of rigid-flexible circuit board manufacturing. Automated processes such as robotic soldering and pick-and-place machines have streamlined production and improved efficiency.

By automating repetitive tasks, manufacturers can reduce the risk of human error and increase the speed at which circuit boards are produced.

Furthermore, advancements in software have revolutionized the design process for rigid-flexible circuit boards. Computer-aided design (CAD) software allows engineers to create complex layouts and simulations, ensuring that the final product meets the necessary specifications. By using CAD software, manufacturers can test different design configurations and make adjustments before production begins, saving time and resources in the long run.

As the demand for smaller, lighter, and more powerful electronic devices continues to grow, the need for cutting-edge rigid-flexible circuit board manufacturing will only increase. By incorporating laser technology, advanced materials, automation, and software into the production process, manufacturers can create circuit boards that are not only more reliable and efficient but also more cost-effective.

In conclusion, the advancements in rigid-flexible circuit board manufacturing have paved the way for a new era of electronics design and production.

By embracing new technologies and processes, manufacturers can stay ahead of the curve and meet the demands of an ever-evolving industry. With continued innovation and collaboration, the future of rigid-flexible circuit board manufacturing looks brighter than ever.