Advantages of Using Cutting-Edge Rigid-Flex PCB Technology

In the world of electronics manufacturing, staying ahead of the curve is essential to remain competitive.

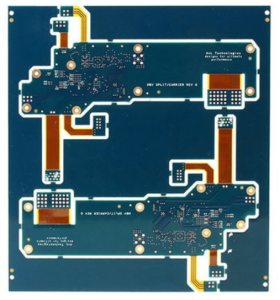

One technology that is revolutionizing the industry is cutting-edge rigid-flex PCB technology.

Rigid-flex PCBs combine the best of both rigid and flexible PCBs, offering a unique set of advantages that make them ideal for a wide range of applications.

One of the key advantages of using cutting-edge rigid-flex PCB technology is their flexibility.

Traditional rigid PCBs are limited in their ability to bend or flex, which can be a significant drawback in certain applications.

Rigid-flex PCBs, on the other hand, are designed to be flexible, allowing them to be bent or folded to fit into tight spaces or conform to the shape of the device they are being used in. This flexibility opens up a whole new world of possibilities for designers, enabling them to create smaller, more compact devices that would not be possible with traditional rigid PCBs.

Another advantage of cutting-edge rigid-flex PCB technology is their durability.

Traditional rigid PCBs are prone to damage from bending or flexing, which can lead to issues such as cracked traces or broken components.

Rigid-flex PCBs, on the other hand, are designed to withstand bending and flexing without compromising their performance or reliability.

This makes them ideal for applications where the PCB may be subject to repeated bending or flexing, such as in wearable devices or automotive applications.

In addition to their flexibility and durability, cutting-edge rigid-flex PCB technology also offers improved signal integrity.

Traditional rigid PCBs can suffer from signal loss or interference due to the presence of vias or connectors, which can degrade the performance of the device. Rigid-flex PCBs, on the other hand, are designed to minimize signal loss and interference, resulting in improved signal integrity and overall performance.

This makes them ideal for high-speed applications where signal integrity is critical, such as in telecommunications or data storage devices.

Furthermore, cutting-edge rigid-flex PCB technology offers improved thermal management.

Traditional rigid PCBs can struggle to dissipate heat effectively, which can lead to issues such as overheating or thermal stress on components.

Rigid-flex PCBs, on the other hand, are designed to provide better thermal management, allowing heat to be dissipated more efficiently and reducing the risk of overheating. This makes them ideal for applications where thermal management is a concern, such as in high-power devices or industrial applications.

Overall, cutting-edge rigid-flex PCB technology offers a wide range of advantages that make them an attractive option for designers and manufacturers alike. Their flexibility, durability, improved signal integrity, and thermal management capabilities make them ideal for a wide range of applications, from consumer electronics to industrial equipment. By embracing this cutting-edge technology, manufacturers can stay ahead of the curve and create innovative, high-performance devices that meet the demands of today’s fast-paced electronics market.