Advanced Materials Used in Rigid Flex PCB Manufacturing

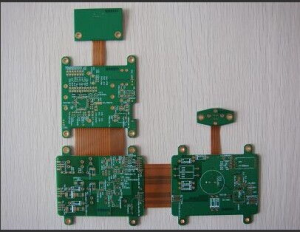

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs.

These boards are made up of both rigid and flexible materials, allowing for greater design flexibility and reliability.

In order to manufacture these cutting-edge PCBs, advanced materials are used to ensure the highest quality and performance.

One of the key materials used in rigid-flex PCB manufacturing is polyimide.

Polyimide is a high-performance polymer that is known for its excellent thermal stability, mechanical strength, and chemical resistance.

This material is used as the flexible substrate in rigid-flex PCBs, allowing the board to bend and flex without compromising its structural integrity.

Polyimide also has a high glass transition temperature, making it ideal for applications that require high temperatures.

Another important material used in rigid-flex PCB manufacturing is copper.

Copper is used as the conductive material in PCBs due to its high electrical conductivity and excellent solderability.

In rigid-flex PCBs, copper is used to create the circuit traces that connect the various components on the board.

Copper is also used as a plating material to create the vias that connect the different layers of the PCB.

The use of copper in rigid-flex PCBs ensures reliable electrical connections and signal integrity.

In addition to polyimide and copper, other advanced materials are used in rigid-flex PCB manufacturing to enhance the performance and reliability of the boards. One such material is solder mask, which is used to protect the copper traces on the PCB from environmental factors such as moisture and dust. Solder mask also helps to prevent solder bridges between adjacent traces, ensuring proper electrical isolation.

Another important material used in rigid-flex PCB manufacturing is adhesive.

Adhesive is used to bond the rigid and flexible layers of the PCB together, creating a strong and reliable connection.

The adhesive used in rigid-flex PCBs is specially formulated to withstand the bending and flexing of the board without delaminating or cracking.

This ensures that the board remains structurally sound even under harsh operating conditions.

Overall, the use of advanced materials in rigid-flex PCB manufacturing is essential to ensure the highest quality and performance of the boards.

These materials provide the necessary flexibility, reliability, and durability to meet the demands of modern electronics applications.

By using cutting-edge materials and manufacturing processes, manufacturers can create rigid-flex PCBs that are at the forefront of technology and innovation.