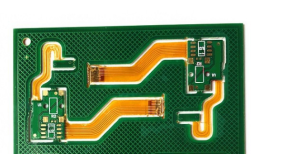

Benefits of Using Cutting-Edge Rigid-Flex PCB Technology in Manufacturing and Assembly

In the world of electronics manufacturing and assembly, the use of cutting-edge rigid-flex PCB technology has become increasingly popular. Rigid-flex PCBs offer a unique combination of flexibility and durability, making them ideal for a wide range of applications.

In this article, we will explore the benefits of using cutting-edge rigid-flex PCB technology in manufacturing and assembly.

One of the key benefits of rigid-flex PCB technology is its ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible PCB materials into a single design, manufacturers can create compact and lightweight products that are easier to transport and handle.

This can be particularly advantageous in industries where space is limited, such as aerospace, automotive, and medical devices.

Another benefit of rigid-flex PCB technology is its ability to improve the reliability and durability of electronic devices.

Traditional PCBs are prone to damage from bending, twisting, and vibration, which can lead to premature failure.

Rigid-flex PCBs, on the other hand, are designed to withstand these types of stresses, making them more reliable and long-lasting.

This can result in lower maintenance costs and fewer warranty claims for manufacturers.

In addition to their durability, rigid-flex PCBs also offer improved signal integrity and EMI/RFI shielding.

The flexible portions of the PCB can be used to route high-speed signals with minimal loss, while the rigid portions can be used to provide a solid ground plane for improved EMI/RFI performance. This can help to reduce signal interference and improve overall system performance, making rigid-flex PCBs an attractive option for high-performance applications.

Furthermore, rigid-flex PCB technology can also streamline the manufacturing and assembly process.

By combining multiple PCBs into a single design, manufacturers can reduce the number of components and interconnects needed, simplifying the assembly process and reducing the risk of errors.

This can lead to faster production times, lower labor costs, and improved overall efficiency for manufacturers.

Overall, the benefits of using cutting-edge rigid-flex PCB technology in manufacturing and assembly are clear.

From reducing size and weight to improving reliability and signal integrity, rigid-flex PCBs offer a range of advantages that make them an attractive option for a wide range of applications.

By leveraging the latest advancements in PCB technology, manufacturers can create innovative and high-performance electronic devices that meet the demands of today’s fast-paced market.