Benefits of Customized Rigid-Flexible PCB Development

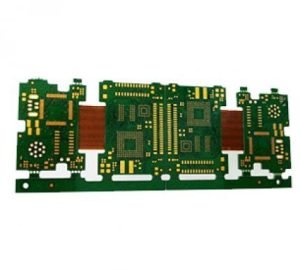

Customized rigid-flexible PCB development offers a wide range of benefits for companies looking to create innovative and reliable electronic products.

These specialized PCBs combine the best of both rigid and flexible circuit board technologies, allowing for greater design flexibility and improved performance. In this article, we will explore some of the key advantages of customized rigid-flexible PCB development.

One of the primary benefits of customized rigid-flexible PCB development is the ability to create complex and compact designs.

By combining rigid and flexible sections on a single board, designers can create intricate layouts that would be impossible with traditional rigid PCBs.

This allows for more efficient use of space within a device, leading to smaller and lighter products that are easier to manufacture and assemble.

Another advantage of customized rigid-flexible PCB development is improved reliability.

The flexible sections of the PCB can be used to create dynamic connections that are less prone to mechanical stress and vibration.

This can help to reduce the risk of component failure and improve the overall lifespan of the product.

Additionally, the use of rigid-flexible PCBs can help to reduce the number of interconnects and solder joints, further enhancing reliability.

Customized rigid-flexible PCB development also offers enhanced signal integrity.

By carefully designing the layout of the PCB, designers can minimize signal interference and crosstalk, leading to improved performance and reduced electromagnetic interference. This can be particularly important for high-speed and high-frequency applications where signal integrity is critical.

In addition to these technical benefits, customized rigid-flexible PCB development can also offer cost savings.

While the initial investment in customized PCB development may be higher than traditional PCBs, the long-term benefits can outweigh the upfront costs.

By creating more efficient and reliable designs, companies can reduce the need for repairs and replacements, ultimately saving money in the long run.

Furthermore, customized rigid-flexible PCB development can also help to streamline the manufacturing process.

By consolidating multiple PCBs into a single rigid-flexible design, companies can reduce the number of components and assembly steps required.

This can lead to faster production times, lower labor costs, and improved overall efficiency.

Overall, customized rigid-flexible PCB development offers a wide range of benefits for companies looking to create innovative and reliable electronic products. From improved design flexibility and reliability to enhanced signal integrity and cost savings, the advantages of customized rigid-flexible PCB development are clear. By investing in customized PCB development, companies can create products that are smaller, lighter, more reliable, and more cost-effective, ultimately giving them a competitive edge in the marketplace.