Customization: Tailored Solutions with Rigid-Flex PCBs

In the rapidly advancing world of electronics, one-size-fits-all solutions are often insufficient to meet the unique demands of modern devices.

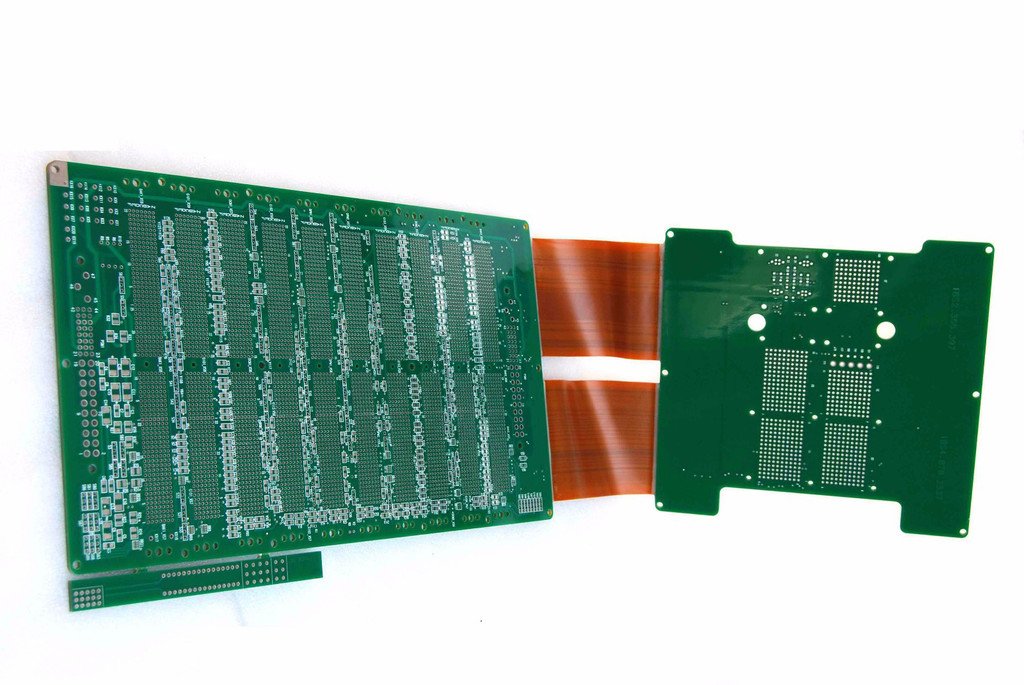

Rigid-flex printed circuit boards (PCBs) have emerged as a highly customizable technology, offering tailored solutions for specific applications.

This ability to adapt to unique device requirements makes rigid-flex PCBs an invaluable tool for engineers and designers across industries.

One of the most significant advantages of rigid-flex PCBs is their ability to be customized in terms of shape, size, and functionality.

Unlike traditional rigid PCBs, which are limited to flat, rectangular designs, rigid-flex PCBs can be designed to fit into irregular or compact spaces.

This flexibility is particularly useful in applications such as wearable devices, medical equipment, and aerospace systems, where space constraints and unique form factors are common. For example, a rigid-flex PCB can be designed to wrap around the curved surface of a smartwatch or fit seamlessly into the compact housing of a hearing aid.

The customization capabilities of rigid-flex PCBs extend beyond physical design.

Engineers can tailor the electrical properties of the board to meet specific performance requirements.

This includes optimizing the number of layers, selecting materials with specific thermal or electrical characteristics, and designing custom trace layouts to minimize signal loss and interference. Such customization is critical in high-performance applications like 5G communication devices, where signal integrity and thermal management are paramount.

Another area where rigid-flex PCBs excel is in meeting the mechanical and environmental demands of specialized applications.

For instance, in automotive electronics, rigid-flex PCBs can be designed to withstand extreme temperatures, vibrations, and exposure to moisture.

Similarly, in aerospace and defense applications, they can be customized to endure harsh conditions such as high altitude, radiation, and mechanical stress. This level of customization ensures that the PCB performs reliably in even the most challenging environments.

The medical industry also benefits greatly from the customization potential of rigid-flex PCBs.

Medical devices often require highly specialized designs to meet strict regulatory standards and patient needs.

For example, implantable devices such as pacemakers or neurostimulators demand compact, lightweight, and biocompatible PCBs that can operate reliably within the human body. Rigid-flex PCBs can be customized to meet these exacting requirements, enabling the development of life-saving technologies.

Furthermore, the ability to customize rigid-flex PCBs allows for rapid prototyping and iterative design.

Engineers can quickly modify the design to test new concepts or address specific challenges, reducing development time and costs.

This agility is particularly valuable in industries like consumer electronics, where time-to-market is critical.

In conclusion, the customization capabilities of rigid-flex PCBs make them an essential technology for meeting the unique requirements of modern devices.

By offering tailored solutions in terms of design, performance, and durability, rigid-flex PCBs empower engineers to push the boundaries of innovation.

As the demand for specialized electronics continues to grow, rigid-flex PCBs will remain at the forefront of technological advancement, enabling the creation of smarter, more efficient, and more reliable devices.