Benefits of Using Rigid Flex PCBs for Cost Efficiency

Cost efficiency is a crucial factor in the world of electronics manufacturing. Companies are constantly looking for ways to reduce costs without compromising on quality or performance.

One way to achieve cost efficiency in PCB assembly is by using rigid flex PCBs.

While these boards may have a higher initial cost compared to traditional PCBs, they can actually help reduce overall assembly costs in the long run.

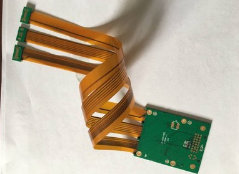

Rigid flex PCBs are a combination of rigid and flexible PCBs, offering the best of both worlds.

The rigid sections provide stability and support for components, while the flexible sections allow for greater design flexibility and space savings.

This unique combination can lead to a reduction in the number of individual components and connectors needed for a given design, ultimately resulting in cost savings.

By minimizing the number of components and connectors, rigid flex PCBs can streamline the assembly process.

With fewer parts to handle and solder, assembly time is reduced, leading to lower labor costs.

Additionally, the risk of errors during assembly is also reduced, further contributing to cost savings.

Furthermore, the use of rigid flex PCBs can also lead to savings in terms of material costs. With fewer components and connectors required, less material is needed for each board.

This can result in lower material costs per unit, especially for high-volume production runs. Additionally, the reduced size and weight of rigid flex PCBs can also lead to savings in shipping and handling costs.

Another benefit of using rigid flex PCBs for cost efficiency is the potential for increased reliability. With fewer components and connectors, there are fewer points of failure in the assembly.

This can lead to improved overall reliability and reduced maintenance costs over the lifespan of the product.

In industries where downtime is costly, such as aerospace or medical devices, the reliability of rigid flex PCBs can provide significant cost savings in the long run.

In addition to cost savings, rigid flex PCBs also offer other benefits that can contribute to overall cost efficiency.

For example, the compact size and lightweight nature of these boards can lead to savings in terms of space and weight requirements.

This can be particularly advantageous in applications where size and weight constraints are critical, such as in portable electronics or wearable devices.

Furthermore, the design flexibility of rigid flex PCBs can also lead to cost savings in terms of product development.

With the ability to create complex and compact designs, engineers can optimize the layout of components and connectors, leading to more efficient use of space and resources.

This can result in faster time-to-market and lower development costs for new products.

In conclusion, while rigid flex PCBs may have a higher initial cost compared to traditional PCBs, their cost efficiency benefits can make them a smart choice for many applications.

By reducing the number of components and connectors, streamlining the assembly process, and improving reliability, rigid flex PCBs can help companies save money in the long run.

With their compact size, lightweight nature, and design flexibility, these boards offer a cost-effective solution for a wide range of electronic applications.