Benefits of Using Rigid-Flex PCBs in Compact Electronics

In the world of compact electronics, every millimeter of space is precious.

Designers and engineers are constantly looking for ways to maximize efficiency and functionality while minimizing size and cost.

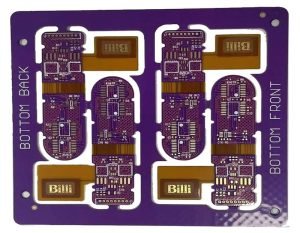

One solution that has gained popularity in recent years is the use of rigid-flex PCBs.

Rigid-flex PCBs offer a unique combination of flexibility and rigidity that allows for more compact and reliable designs.

By combining rigid and flexible materials in a single board, designers can create complex three-dimensional shapes that would be impossible with traditional PCBs.

This flexibility allows for more efficient use of space, making rigid-flex PCBs ideal for compact electronics such as smartphones, wearables, and medical devices.

One of the key benefits of using rigid-flex PCBs in compact electronics is cost-effectiveness.

While the initial cost of rigid-flex PCBs may be higher than traditional PCBs, the overall cost savings can be significant. Because rigid-flex PCBs eliminate the need for additional connectors and cables, they can reduce assembly time and labor costs.

Additionally, the reliability of rigid-flex PCBs can lead to fewer warranty claims and repairs, further reducing costs in the long run.

Another benefit of using rigid-flex PCBs in compact electronics is improved reliability.

The flexible materials used in rigid-flex PCBs are more resistant to vibration and shock, making them ideal for applications where durability is a concern. Additionally, the elimination of connectors and cables reduces the risk of connection failures, improving overall reliability.

In addition to cost-effectiveness and reliability, rigid-flex PCBs offer a number of other benefits for compact electronics.

For example, the compact size of rigid-flex PCBs allows for more efficient use of space, making it easier to design smaller and more lightweight devices. This can be particularly important in applications where size and weight are critical, such as wearable technology and medical devices.

Furthermore, the flexibility of rigid-flex PCBs allows for more creative and innovative designs.

Designers can create unique shapes and configurations that would be impossible with traditional PCBs, opening up new possibilities for compact electronics.

This flexibility also allows for more efficient routing of traces and components, reducing signal interference and improving overall performance.

Overall, the benefits of using rigid-flex PCBs in compact electronics are clear.

From cost-effectiveness and reliability to improved space efficiency and creative design possibilities, rigid-flex PCBs offer a number of advantages for designers and engineers looking to create compact and innovative electronic devices.

By taking advantage of the unique properties of rigid-flex PCBs, designers can create smaller, more reliable, and more cost-effective products that push the boundaries of what is possible in the world of compact electronics.