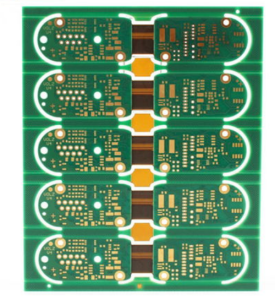

Overcoming Material Limitations in Rigid-Flex PCB Design

Designing and manufacturing rigid-flex printed circuits can be a complex and challenging process.

These circuits, which combine both rigid and flexible materials, offer a number of advantages in terms of space savings, weight reduction, and improved reliability. However, they also present unique challenges that must be overcome in order to ensure a successful end product.

One of the primary challenges in designing and manufacturing rigid-flex printed circuits is the selection of materials.

Rigid-flex circuits require materials that can withstand the bending and flexing that they will be subjected to during use.

This means that both the rigid and flexible portions of the circuit must be made from materials that are both durable and flexible.

Finding materials that meet these requirements can be difficult, as many traditional circuit materials are not well-suited to the demands of rigid-flex designs.

In addition to material selection, another challenge in designing and manufacturing rigid-flex circuits is ensuring that the circuit is able to withstand the stresses and strains that it will be subjected to during use. Rigid-flex circuits are often used in applications where they will be bent, twisted, or otherwise flexed on a regular basis. This means that the circuit must be designed in such a way that it can withstand these movements without breaking or failing.

This requires careful attention to detail in the design process, as well as thorough testing to ensure that the circuit will perform as expected under real-world conditions.

Another challenge in designing and manufacturing rigid-flex circuits is ensuring that the circuit is able to meet the electrical requirements of the application. Rigid-flex circuits are often used in applications where space is at a premium, which means that they must be able to pack a lot of functionality into a small footprint. This can be challenging, as it requires careful routing of traces and components in order to ensure that the circuit meets the necessary electrical specifications. In addition, the flexible portions of the circuit can introduce additional challenges, as they may not be able to support the same level of electrical performance as the rigid portions.

Despite these challenges, there are a number of strategies that can be employed to overcome them and successfully design and manufacture rigid-flex printed circuits. One approach is to work closely with a manufacturer that specializes in rigid-flex PCBs. These manufacturers have the expertise and experience necessary to navigate the complexities of rigid-flex design and can provide valuable guidance throughout the process. Additionally, using advanced design tools and simulation software can help to identify potential issues early in the design process, allowing for adjustments to be made before production begins.

In conclusion, designing and manufacturing rigid-flex printed circuits presents a number of challenges that must be overcome in order to ensure a successful end product. By carefully selecting materials, designing for durability and flexibility, and meeting electrical requirements, it is possible to create high-quality rigid-flex circuits that meet the needs of a wide range of applications. Working with experienced manufacturers and utilizing advanced design tools can help to streamline the process and ensure a successful outcome.