Optimizing Design for Manufacturing Challenges in Rigid-Flex PCB Production

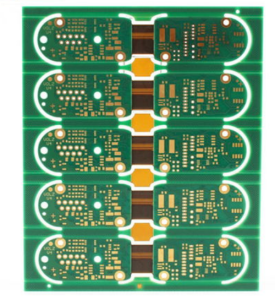

Rigid-flex PCBs have become increasingly popular in the healthcare industry due to their ability to provide a compact and reliable solution for medical devices.

However, the production of rigid-flex PCBs presents unique challenges that must be addressed to ensure the highest quality and reliability of the final product.

One of the key challenges in rigid-flex PCB production for healthcare is optimizing the design for manufacturing.

Designing a rigid-flex PCB that meets the specific requirements of a medical device while also being manufacturable can be a complex task.

Designers must consider factors such as the size and shape of the PCB, the placement of components, and the routing of traces to ensure that the final product will meet the necessary performance and reliability standards.

To address these challenges, designers can use design for manufacturing (DFM) principles to optimize the design of the rigid-flex PCB for manufacturability.

By working closely with the PCB manufacturer early in the design process, designers can identify potential manufacturing issues and make design modifications to address them.

This collaborative approach can help to streamline the production process and reduce the risk of costly errors or delays.

Another challenge in rigid-flex PCB production for healthcare is ensuring the reliability of the final product.

Medical devices must meet strict regulatory requirements for safety and performance, and any failure in the PCB could have serious consequences for patient health.

To address this challenge, manufacturers must implement rigorous quality control processes throughout the production process to ensure that the final product meets the necessary standards.

One solution to this challenge is to use advanced testing techniques to verify the quality and reliability of the rigid-flex PCB.

In-circuit testing, flying probe testing, and automated optical inspection are just a few of the testing methods that can be used to identify any defects or issues in the PCB before it is assembled into the final product.

By conducting thorough testing at each stage of the production process, manufacturers can ensure that the final product will meet the necessary performance and reliability standards.

In addition to optimizing the design for manufacturing and ensuring the reliability of the final product, manufacturers must also address the challenge of cost-effectiveness in rigid-flex PCB production for healthcare.

Medical devices are often produced in relatively low volumes compared to consumer electronics, which can make the production of rigid-flex PCBs more expensive.

To address this challenge, manufacturers must find ways to reduce costs without compromising on quality or reliability.

One solution to this challenge is to work with a PCB manufacturer that specializes in rigid-flex PCB production for healthcare.

These manufacturers have the expertise and experience to optimize the production process and reduce costs without sacrificing quality.

By working with a specialized manufacturer, healthcare companies can ensure that they are getting the best possible value for their investment in rigid-flex PCB production.

In conclusion, the production of rigid-flex PCBs for healthcare presents unique challenges that must be addressed to ensure the highest quality and reliability of the final product. By optimizing the design for manufacturing, ensuring the reliability of the final product, and finding cost-effective solutions, manufacturers can overcome these challenges and produce high-quality rigid-flex PCBs for medical devices. By working closely with experienced PCB manufacturers and implementing advanced testing techniques, healthcare companies can ensure that their medical devices meet the necessary regulatory requirements and provide safe and effective solutions for patients.