Overcoming Alignment Issues in Rigid Flex PCB Assembly

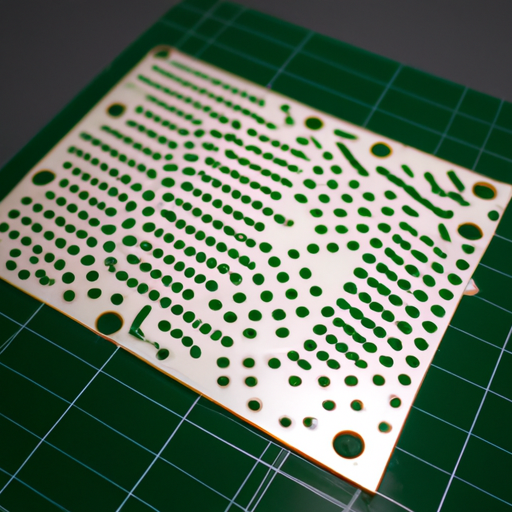

Rigid flex PCBs offer a unique solution for electronic devices that require both flexibility and rigidity in their design.

However, the assembly process for these boards can present some challenges, particularly when it comes to alignment issues.

Ensuring that the rigid and flexible portions of the PCB are properly aligned is crucial for the overall functionality and reliability of the device.

In this article, we will explore some of the common alignment issues that can arise during rigid flex PCB assembly and discuss potential solutions to overcome them.

One of the main alignment issues that can occur during rigid flex PCB assembly is misalignment between the rigid and flexible portions of the board.

This can lead to issues such as poor electrical connections, mechanical stress on the board, and ultimately, a non-functional device.

Misalignment can occur due to a variety of factors, including inaccuracies in the design files, errors in the manufacturing process, or even thermal expansion during soldering.

To address misalignment issues, it is important to carefully review the design files before manufacturing to ensure that all components are properly placed and aligned.

Additionally, using advanced manufacturing techniques such as laser drilling and automated assembly can help to improve the accuracy of the assembly process and reduce the likelihood of misalignment.

During the soldering process, it is important to carefully monitor the temperature to prevent thermal expansion from causing misalignment between the rigid and flexible portions of the board.

Another common alignment issue in rigid flex PCB assembly is warping or bending of the board.

This can occur due to uneven stress during the manufacturing process, improper handling of the board, or even environmental factors such as temperature fluctuations.

Warping or bending of the board can lead to issues such as poor electrical connections, component damage, and overall reduced reliability of the device.

To prevent warping or bending of the board, it is important to use high-quality materials that are designed to withstand the stresses of the assembly process. Additionally, implementing proper handling procedures and storage conditions can help to minimize the risk of warping or bending.

During the assembly process, it is important to carefully monitor the temperature and humidity levels to prevent environmental factors from affecting the board.

In conclusion, alignment issues are a common challenge in rigid flex PCB assembly, but with careful planning and attention to detail, these issues can be overcome.

By reviewing design files, using advanced manufacturing techniques, and implementing proper handling procedures, it is possible to ensure that the rigid and flexible portions of the board are properly aligned.

By addressing alignment issues early in the assembly process, manufacturers can improve the overall functionality and reliability of their devices.