Overcoming Design Challenges in Rigid Flex PCBs for IoT

The Internet of Things (IoT) has revolutionized the way we interact with technology, allowing for seamless connectivity between devices and systems.

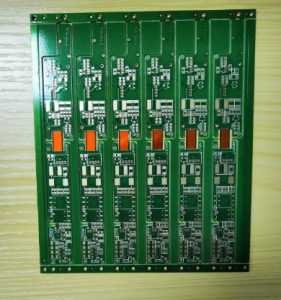

As IoT continues to grow, the demand for more advanced and complex electronic components, such as rigid flex PCBs, has also increased.

Rigid flex PCBs offer a unique combination of flexibility and durability, making them ideal for IoT applications where space is limited and reliability is crucial.

However, producing rigid flex PCBs for IoT comes with its own set of challenges.

One of the main challenges is designing a PCB that can withstand the rigors of everyday use while maintaining the flexibility needed for the application.

This requires careful consideration of materials, layout, and manufacturing processes to ensure that the PCB meets the necessary performance requirements.

Another challenge in producing rigid flex PCBs for IoT is ensuring that the design is optimized for the specific application.

This includes factors such as signal integrity, thermal management, and mechanical stability.

Designing a PCB that can reliably transmit data, dissipate heat, and withstand physical stress is essential for the success of an IoT device.

To overcome these challenges, designers and manufacturers must work closely together to develop a comprehensive design strategy that takes into account all aspects of the PCB’s performance.

This may involve using advanced simulation tools to analyze the PCB’s behavior under different conditions, as well as conducting thorough testing to validate the design before production.

In addition to design challenges, producing rigid flex PCBs for IoT also requires careful attention to manufacturing processes.

The unique construction of rigid flex PCBs, which combine rigid and flexible materials in a single board, presents challenges in terms of assembly and testing.

Specialized equipment and techniques are needed to ensure that the PCB is assembled correctly and that all connections are secure.

One solution to this challenge is to work with experienced manufacturers who have the expertise and capabilities to produce high-quality rigid flex PCBs for IoT applications.

By partnering with a trusted manufacturer, designers can ensure that their PCBs are produced to the highest standards and meet the specific requirements of their application.

Furthermore, advancements in manufacturing technology, such as automated assembly and inspection systems, have made it easier to produce complex PCBs with greater precision and efficiency.

These technologies can help streamline the production process and reduce the risk of errors, resulting in higher-quality PCBs that are more reliable and durable.

Overall, producing rigid flex PCBs for IoT presents a unique set of challenges that require careful planning and collaboration between designers and manufacturers. By addressing design considerations, optimizing manufacturing processes, and leveraging advanced technologies, designers can overcome these challenges and create high-performance PCBs that meet the demands of today’s IoT applications. With the right approach and expertise, producing rigid flex PCBs for IoT can be a rewarding and successful endeavor.