Integrating Rigid-Flex PCBs in Medical Technologies: A Case Study of Successful Implementation

In the ever-evolving field of medical technology, the integration of rigid-flex PCBs has become increasingly prevalent.

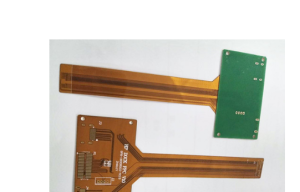

These innovative circuit boards offer a unique combination of flexibility and rigidity, making them ideal for use in medical devices that require both durability and adaptability.

In this article, we will explore several case studies that highlight the successful integration of rigid-flex PCBs in various medical technologies.

One such case study involves the development of a wearable health monitoring device.

The device, designed to track vital signs and provide real-time data to healthcare professionals, required a compact and lightweight design to ensure comfort and ease of use for patients.

By incorporating rigid-flex PCBs into the device’s construction, the design team was able to create a flexible and durable circuit board that could withstand the rigors of daily wear while maintaining the necessary electrical connections for accurate data collection.

Another case study focuses on the integration of rigid-flex PCBs in a surgical robot.

The robot, used for minimally invasive procedures, required a high degree of precision and reliability to ensure successful outcomes for patients.

By utilizing rigid-flex PCBs in the robot’s control system, the design team was able to create a compact and efficient circuit board that could withstand the mechanical stresses of the surgical environment while providing the necessary electrical connections for precise control of the robot’s movements.

In both of these case studies, the successful integration of rigid-flex PCBs was made possible through careful planning and collaboration between design teams, manufacturers, and medical professionals.

By understanding the unique requirements of each medical technology and leveraging the flexibility and durability of rigid-flex PCBs, these teams were able to create innovative solutions that improved patient outcomes and advanced the field of medical technology.

The use of rigid-flex PCBs in medical technologies offers numerous benefits, including increased reliability, reduced size and weight, and improved performance.

By integrating these advanced circuit boards into their designs, medical device manufacturers can create products that are more durable, flexible, and efficient, ultimately leading to better outcomes for patients.

As the field of medical technology continues to evolve, the integration of rigid-flex PCBs will likely become even more widespread.

By studying successful case studies like the ones mentioned in this article, design teams can gain valuable insights into the best practices for incorporating rigid-flex PCBs into their own medical technologies. With careful planning, collaboration, and innovation, the successful integration of rigid-flex PCBs can help drive advancements in medical technology and improve patient care around the world.