Key Considerations for Testing Rigid Flex PCBs Before Production

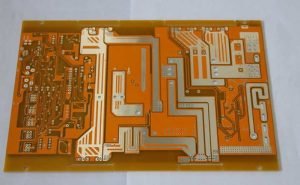

Rigid flex PCBs are a popular choice for many electronic devices due to their flexibility and durability. However, testing these complex boards before production is crucial to ensure they meet quality standards and function properly. In this article, we will discuss some best practices for testing rigid flex PCBs before production to help manufacturers avoid costly errors and delays.

One key consideration when testing rigid flex PCBs is to establish a comprehensive testing plan that covers all aspects of the board’s functionality.

This includes testing for electrical continuity, signal integrity, and mechanical reliability. By conducting thorough testing at each stage of the production process, manufacturers can identify and address any issues early on, reducing the risk of defects in the final product.

Another important aspect of testing rigid flex PCBs is to use the right testing equipment and techniques.

This may include using automated testing equipment to ensure consistency and accuracy in the testing process.

Additionally,manufacturers should consider using specialized testing fixtures designed specifically for rigid flex PCBs to ensure proper alignment and contact with the board.

In addition to electrical testing, it is also important to test the mechanical reliability of rigid flex PCBs. This includes testing for bendability, flex fatigue, and thermal cycling to ensure the board can withstand the rigors of everyday use. By conducting these tests, manufacturers can identify any weak points in the design and make necessary adjustments to improve the board’s overall reliability.

Furthermore, manufacturers should consider conducting environmental testing to ensure the rigid flex PCB can withstand harsh conditions such as temperature extremes, humidity, and vibration. By subjecting the board to these conditions during testing, manufacturers can identify any potential issues that may arise in real-world use and make necessary design changes to improve the board’s durability.

When testing rigid flex PCBs before production, it is also important to involve all stakeholders in the testing process.

This includes design engineers, production engineers, and quality control personnel who can provide valuable insights and feedback on the board’s performance. By collaborating with all stakeholders, manufacturers can ensure that the board meets all requirements and specifications before moving into full-scale production.

In conclusion, testing rigid flex PCBs before production is essential to ensure the board meets quality standards and functions properly.

By establishing a comprehensive testing plan, using the right equipment and techniques, and involving all stakeholders in the testing process, manufacturers can identify and address any issues early on, reducing the risk of defects in the final product. By following these best practices, manufacturers can produce high-quality rigid flex PCBs that meet the demands of today’s electronic devices.