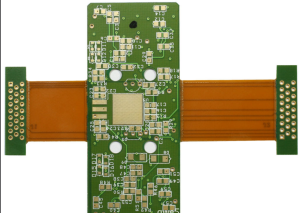

Benefits of Proper Stackup Design in Multi-Layer Rigid-Flex Boards

Stackup design is a critical aspect of designing multi-layer rigid-flex boards.

Proper stackup design can have a significant impact on the performance, reliability, and manufacturability of the final product.

In this article, we will discuss the benefits of proper stackup design in multi-layer rigid-flex boards and provide some best practices to help you achieve optimal results.

One of the key benefits of proper stackup design is improved signal integrity.

By carefully designing the stackup, you can minimize signal interference and crosstalk between different layers of the board.

This can help ensure that signals are transmitted accurately and reliably, leading to better overall performance of the board.

Another benefit of proper stackup design is improved thermal management.

By strategically placing power and ground planes within the stackup, you can help dissipate heat more effectively and prevent hot spots on the board.

This can help improve the reliability of the board and extend its lifespan.

Proper stackup design can also help reduce electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues.

By carefully designing the stackup to minimize loop areas and control impedance, you can reduce the risk of EMI and EMC problems that can cause signal degradation or even board failure.

In addition to improving performance and reliability, proper stackup design can also make the manufacturing process more efficient.

By designing the stackup with manufacturability in mind, you can reduce the risk of errors during fabrication and assembly.

This can help streamline the production process and reduce time to market for your product.

To achieve optimal results with stackup design in multi-layer rigid-flex boards, there are several best practices that you should follow.

First, carefully consider the number of layers in the board and the placement of power and ground planes.

By strategically placing these planes within the stackup, you can help improve signal integrity and thermal management.

Next, pay attention to the impedance control of signal traces within the stackup.

By designing the stackup to control impedance, you can ensure that signals are transmitted accurately and reliably.

This is especially important for high-speed digital signals, where impedance mismatches can lead to signal degradation.

It is also important to consider the material properties of the board when designing the stackup.

Different materials have different dielectric constants and loss tangents, which can affect signal integrity and thermal management.

By selecting the right materials for your stackup, you can optimize the performance of the board.

Finally, consider the mechanical constraints of the board when designing the stackup.

Rigid-flex boards have unique mechanical requirements due to their flexible sections.

By designing the stackup to accommodate these constraints, you can ensure that the board will function properly and withstand the rigors of use.

In conclusion, proper stackup design is essential for achieving optimal performance, reliability, and manufacturability in multi-layer rigid-flex boards.

By following best practices and carefully considering the various aspects of stackup design, you can create a board that meets your requirements and exceeds your expectations.