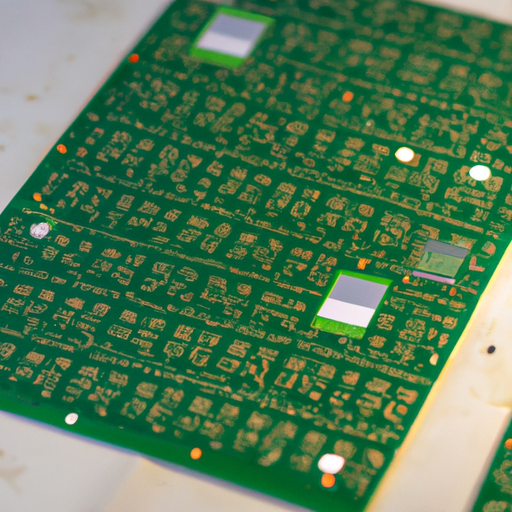

Design Considerations for Rigid Flex PCBs

Rigid-flex PCBs have become increasingly popular in the electronics industry due to their ability to combine the benefits of both rigid and flexible PCBs in one design.

However, designing and producing rigid-flex PCBs can be a complex process that requires careful consideration of various factors to ensure optimal performance and reliability.

In this article, we will discuss some best practices for rigid-flex PCB production to help you achieve the best results.

One of the most important considerations when designing a rigid-flex PCB is the placement of components and routing of traces.

It is essential to carefully plan the layout of the PCB to ensure that all components fit within the designated space and that traces are routed efficiently to minimize signal interference.

When designing a rigid-flex PCB, it is crucial to consider the mechanical constraints of the design, such as bend radius and flexing cycles, to ensure that the PCB can withstand the intended use without compromising performance.

Another important aspect of rigid-flex PCB production is the selection of materials.

The choice of materials can have a significant impact on the performance and reliability of the PCB.

It is essential to select materials that can withstand the mechanical stresses of flexing and bending without compromising electrical performance.

Additionally, choosing materials with good thermal conductivity can help dissipate heat more effectively, improving the overall reliability of the PCB.

In addition to materials, it is also important to consider the manufacturing process when producing rigid-flex PCBs.

The manufacturing process for rigid-flex PCBs is more complex than that of traditional rigid PCBs, requiring specialized equipment and expertise.

It is essential to work with a manufacturer that has experience in producing rigid-flex PCBs to ensure that the final product meets your specifications and quality standards.

When designing a rigid-flex PCB, it is also important to consider the environmental conditions in which the PCB will be used.

Factors such as temperature, humidity, and vibration can all impact the performance and reliability of the PCB.

It is essential to design the PCB with these factors in mind and select materials that can withstand the intended environmental conditions.

Testing is another critical aspect of rigid-flex PCB production.

It is essential to thoroughly test the PCB to ensure that it meets all specifications and quality standards before it is put into production.

Testing can help identify any potential issues early on and prevent costly rework or recalls down the line.

In conclusion, designing and producing rigid-flex PCBs requires careful consideration of various factors to ensure optimal performance and reliability.

By following best practices for rigid-flex PCB production, you can create high-quality PCBs that meet your specifications and quality standards.

Working with an experienced manufacturer and testing the PCB thoroughly can help ensure that your rigid-flex PCBs perform reliably in the intended application.