Benefits of Using Rigid Flex PCBs in Electronic Devices

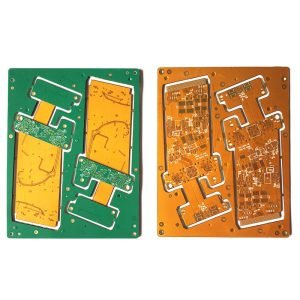

Rigid-flex PCBs, or printed circuit boards, have become increasingly popular in the electronics industry due to their unique design and numerous advantages. These boards combine the benefits of both rigid and flexible PCBs, offering a versatile solution for a wide range of electronic devices.

In this article, we will explore the applications and advantages of rigid-flex PCBs in electronic devices.

One of the key advantages of rigid-flex PCBs is their ability to reduce the overall size and weight of electronic devices.

By combining rigid and flexible sections in a single board, designers can create compact and lightweight solutions that are ideal for space-constrained applications. This is particularly beneficial in devices such as smartphones, tablets, and wearables, where size and weight are critical factors.

Another advantage of rigid-flex PCBs is their enhanced reliability and durability.

Traditional rigid PCBs are prone to mechanical stress and vibration, which can lead to solder joint failures and other reliability issues.

Rigid-flex PCBs, on the other hand, are more resistant to these types of stresses due to their flexible sections, resulting in a more robust and reliable solution for electronic devices.

Rigid-flex PCBs also offer improved signal integrity and EMI performance compared to traditional rigid PCBs.

The flexible sections of the board act as a buffer, reducing signal interference and improving overall signal quality.

This is particularly important in high-speed and high-frequency applications, where signal integrity is critical for the proper functioning of the device.

In terms of applications, rigid-flex PCBs are used in a wide range of electronic devices, including medical devices, aerospace systems, automotive electronics, and consumer electronics. In the medical industry, rigid-flex PCBs are used in devices such as pacemakers, defibrillators, and medical implants, where reliability and durability are paramount. In the aerospace industry, rigid-flex PCBs are used in avionics systems, communication systems, and navigation equipment, where size, weight, and reliability are critical factors.

In the automotive industry, rigid-flex PCBs are used in electronic control units, sensors, and infotainment systems, where space constraints and reliability are key considerations. In consumer electronics, rigid-flex PCBs are used in smartphones, tablets, wearables, and other portable devices, where size, weight, and signal integrity are important factors.

Overall, rigid-flex PCBs offer a versatile and reliable solution for a wide range of electronic devices. Their unique design allows for compact and lightweight solutions, while also providing enhanced reliability, signal integrity, and EMI performance. With their numerous advantages and applications, rigid-flex PCBs are sure to continue playing a key role in the electronics industry for years to come.