Benefits of Using Rigid-Flex PCBs in Medical Devices

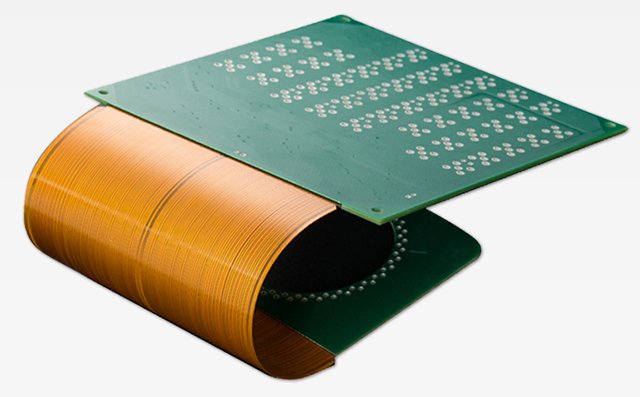

Rigid-flex PCBs, or rigid-flex printed circuit boards, have become increasingly popular in various industries due to their unique design and flexibility.

One of the key application fields where rigid-flex PCBs are being widely used is in medical devices.

These specialized PCBs offer numerous benefits that make them ideal for use in medical equipment, such as pacemakers, defibrillators, and medical imaging devices.

One of the primary advantages of using rigid-flex PCBs in medical devices is their ability to withstand harsh environments and extreme conditions. Medical equipment often needs to operate in challenging environments, such as high temperatures, humidity, and vibration.

Rigid-flex PCBs are designed to be durable and reliable, making them well-suited for use in medical devices that need to perform consistently in demanding conditions.

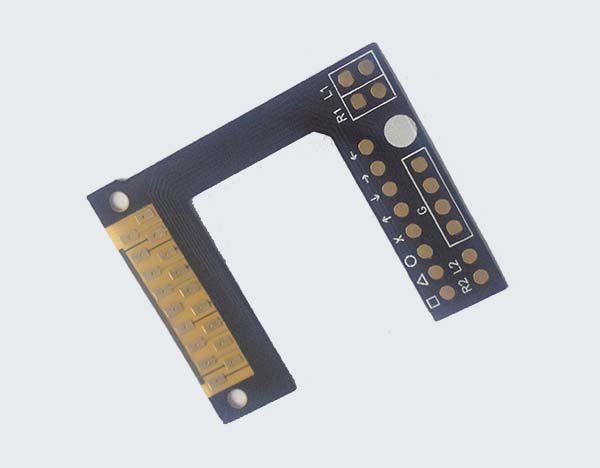

In addition to their durability, rigid-flex PCBs offer a high level of flexibility in terms of design and layout.

This flexibility allows for the creation of compact and lightweight medical devices that can be easily integrated into a patient’s body or used in portable medical equipment.

The ability to design complex and intricate circuits on a single board also helps to reduce the overall size of the device, making it more convenient for both patients and healthcare professionals.

Furthermore, rigid-flex PCBs are known for their excellent signal integrity and electrical performance. Medical devices require precise and accurate data transmission to ensure the proper functioning of the equipment and the safety of the patient.

Rigid-flex PCBs are designed to minimize signal loss and interference, resulting in reliable and consistent performance in medical devices.

Another key benefit of using rigid-flex PCBs in medical devices is their cost-effectiveness.

While the initial cost of manufacturing rigid-flex PCBs may be higher than traditional PCBs, the long-term benefits outweigh the upfront investment.

Rigid-flex PCBs have a longer lifespan and require less maintenance, reducing the overall cost of ownership for medical device manufacturers.

The market prospects for rigid-flex PCBs in the medical device industry are promising, with an increasing demand for advanced and innovative medical equipment.

As technology continues to evolve, the need for smaller, more efficient, and reliable medical devices will drive the adoption of rigid-flex PCBs in the healthcare sector.

Manufacturers are constantly looking for ways to improve the performance and functionality of medical devices, and rigid-flex PCBs offer a solution that meets these requirements.

In conclusion, the application fields and market prospects of rigid-flex PCBs in the medical device industry are vast and promising.

These specialized PCBs offer numerous benefits, including durability, flexibility, signal integrity, and cost-effectiveness, making them an ideal choice for use in medical equipment.

As the demand for advanced medical devices continues to grow, rigid-flex PCBs will play a crucial role in driving innovation and improving patient care in the healthcare sector.