AI-Optimized Rigid-Flex PCB Assembly for Next-Gen Wearable Health Monitors

AI-optimized rigid-flex PCB assembly is revolutionizing the development of next-generation wearable health monitors.

As the demand for compact, efficient, and multifunctional health monitoring devices grows, manufacturers increasingly rely on advanced assembly techniques to meet these needs.

This article delves into the intricacies of AI optimization in rigid-flex PCB assembly and how it is enhancing the capabilities of wearable technology.

Understanding Rigid-Flex PCBs

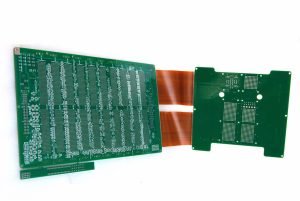

Rigid-flex printed circuit boards (PCBs) combine the best attributes of rigid and flexible PCBs, enabling compact designs that can fit seamlessly into wearable devices.

These boards comprise both rigid and flexible segments, allowing for versatile configurations while minimizing space.

This design is particularly advantageous in wearable health monitors, where form factor, weight, and performance are critical.

Benefits of Rigid-Flex PCB Assembly in Wearable Devices

The integration of rigid-flex technology in health monitors offers several benefits:

- Space Utilization: Rigid-flex PCBs can bend and fold, fitting snugly into the contours of the device without taking up extra space.

This is essential for health wearables, which are often designed to be discreet and lightweight. - Enhanced Durability: Rigid-flex boards are more robust than traditional flexible PCBs.

They are less prone to damage from repeated bending and flexing, ensuring long-term durability in products that benefit from daily wear. - Reduced Assembly Complexity: By integrating different functions into a single board, manufacturers can simplify the assembly process.

This not only speeds up production but also reduces costs, making it feasible to produce high-quality devices at scale.

The Role of AI in PCB Assembly

AI optimization plays a pivotal role in improving the efficiency and accuracy of rigid-flex PCB assembly.

Through data analysis and machine learning, manufacturers can streamline their processes in several key areas:

1. Design Optimization

AI algorithms can analyze previous designs and predict the performance of new configurations.

By simulating different layouts and structures, AI can help designers optimize the PCB for minimal space usage and maximum functionality.

This means engineers can quickly iterate on designs without the usual cumbersome trial-and-error approach.

2. Quality Control

Integration of AI in the assembly line significantly enhances quality control measures.

With computer vision and machine learning, AI systems can monitor production in real-time, identifying defects or inconsistencies more accurately than traditional methods.

This ensures that only high-quality PCBs make it into wearable devices, reducing the risk of failures in the field.

3. Predictive Maintenance

AI can also be leveraged for predictive maintenance of assembly equipment.

By analyzing machine data, AI can forecast when a piece of machinery might fail, allowing manufacturers to perform maintenance before a breakdown occurs.

This minimization of downtime contributes to more efficient production processes.

Future Implications for Wearable Health Monitors

As health technology continues to evolve, AI-optimized rigid-flex PCB assembly will undoubtedly play a crucial role.

The move towards more sophisticated health monitoring solutions, such as real-time biometric tracking or advanced analytics, is possible largely due to these technological advancements.

Challenges and Considerations

Despite the advantages of AI optimization in PCB assembly, several challenges still exist:

- Integration with Existing Systems: Many companies may struggle to integrate AI technologies with their existing manufacturing processes.

Transitioning to AI may require substantial changes in workflow or additional training for staff. - Data Security: As AI systems collect and analyze data, concerns regarding data security and intellectual property protection become paramount.

Manufacturers must implement robust cybersecurity measures to safeguard sensitive information.

Conclusion

AI-optimized rigid-flex PCB assembly represents a significant achievement in the realm of wearable health monitors.

By embracing this technology, manufacturers can produce devices that are not only smaller and more versatile but also more reliable and efficient.

As the health tech landscape continues to advance, integrating these innovations will remain essential for creating next-gen wearable solutions that meet the evolving demands of consumers.

As we step into a future that hinges on technology-driven healthcare, the importance of robust and efficient PCB assembly processes cannot be overstated.