Benefits of AI-Driven Design Optimization in High-Mix Manufacturing

In the fast-paced world of high-mix manufacturing, companies are constantly seeking ways to improve efficiency, reduce costs, and increase productivity.

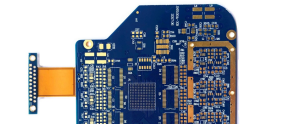

One area where significant gains can be made is in the design optimization of rigid-flex PCBs.

These complex circuit boards are essential components in a wide range of electronic devices, from smartphones to medical devices.

However, designing and manufacturing rigid-flex PCBs can be a costly and time-consuming process, especially in high-mix manufacturing environments where product variations are common.

One solution that is gaining traction in the industry is AI-driven design optimization.

By harnessing the power of artificial intelligence and machine learning algorithms, companies can significantly reduce the time and cost associated

with designing rigid-flex PCBs. These advanced technologies can analyze vast amounts of data and identify the most efficient design configurations,

leading to cost savings of up to 30% in some cases.

One of the key benefits of AI-driven design optimization is its ability to quickly generate and evaluate multiple design options.

Traditional design processes often rely on manual labor and trial-and-error methods, which can be time-consuming and prone to errors.

By contrast, AI algorithms can rapidly explore a wide range of design possibilities, taking into account factors such as material costs, manufacturing constraints,

and performance requirements. This allows companies to identify the most cost-effective design solutions in a fraction of the time it would take using traditional methods.

Another advantage of AI-driven design optimization is its ability to adapt to changing manufacturing conditions.

In high-mix manufacturing environments, product variations and design requirements can change rapidly, making it difficult to keep up with traditional design processes. AI algorithms, however, can quickly adjust to new information and optimize designs on the fly, ensuring that companies can meet changing demands without sacrificing efficiency or quality.

Furthermore, AI-driven design optimization can help companies identify and eliminate potential design flaws before they become costly manufacturing errors.

By analyzing design data and simulating manufacturing processes, AI algorithms can detect issues such as signal interference, thermal hotspots,

and mechanical stress points. This proactive approach can prevent costly rework and delays, ensuring that products are manufactured correctly the first time.

In addition to cost savings and improved efficiency, AI-driven design optimization can also lead to better product performance.

By optimizing designs for factors such as signal integrity, thermal management, and mechanical stability, companies can produce PCBs that meet orexceed performance requirements. This can result in higher-quality products, increased customer satisfaction, and a competitive edge in the marketplace.

Overall, AI-driven design optimization offers a range of benefits for companies engaged in high-mix manufacturing. From cost savings and efficiency gains to improved product performance and quality, AI technologies are revolutionizing the way rigid-flex PCBs are designed and manufactured. By embracing these advanced tools, companies can stay ahead of the competition, reduce time-to-market, and drive innovation in the electronics industry.