The Benefits of Flex Rigid PCBs in Advancing Technology

Flex rigid PCBs, also known as flexible printed circuit boards, have become an essential component in advancing technology.

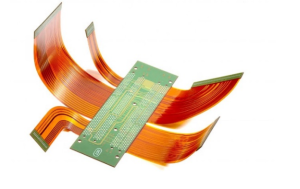

These innovative circuit boards offer a unique combination of flexibility and rigidity, allowing for more compact and efficient electronic devices.

In this article, we will explore the benefits of flex rigid PCBs and how they have revolutionized the electronics industry.

One of the key advantages of flex rigid PCBs is their ability to bend and twist without compromising the integrity of the circuit.

This flexibility allows for more creative and compact designs, making it possible to fit electronics into smaller and more unconventional spaces.

For example, flex rigid PCBs are commonly used in wearable technology, such as smartwatches and fitness trackers, where space is limited and flexibility is essential.

In addition to their flexibility, flex rigid PCBs also offer improved reliability and durability compared to traditional rigid PCBs.

The combination of flexible and rigid sections helps to reduce stress on the circuit, leading to fewer mechanical failures and longer lifespan.

This increased reliability is crucial in industries where electronic devices are subjected to harsh conditions, such as automotive and aerospace.

Furthermore, flex rigid PCBs can help to streamline the manufacturing process and reduce overall costs.

By eliminating the need for multiple interconnects and connectors, these circuit boards simplify assembly and reduce the risk of errors.

This not only saves time and money during production but also improves the overall quality of the final product.

Another benefit of flex rigid PCBs is their ability to improve signal integrity and reduce electromagnetic interference.

The flexible sections of the circuit board can be designed to minimize signal loss and crosstalk, resulting in better performance and reliability.

This is particularly important in high-speed applications, such as data centers and telecommunications, where signal integrity is critical.

Moreover, flex rigid PCBs offer greater design flexibility and customization options compared to rigid PCBs.

Designers can create complex and intricate layouts that would be impossible with traditional circuit boards, allowing for more innovative and efficient electronic devices. This flexibility also makes it easier to incorporate additional features, such as sensors and antennas, into the design.

Overall, the evolution of flex rigid PCBs has had a profound impact on the electronics industry, enabling the development of smaller, more reliable, and more advanced electronic devices. From wearable technology to automotive applications, these innovative circuit boards have revolutionized the way we design and manufacture electronics. As technology continues to advance, flex rigid PCBs will undoubtedly play a crucial role in shaping the future of electronic devices.