Benefits of Using Rigid-Flex PCBs in Medical Devices

Advancements in technology have revolutionized the medical industry, allowing for the development of innovative medical devices that have greatly improved patient care and outcomes.

One such advancement that has played a crucial role in this transformation is the use of rigid-flex PCBs in medical devices.

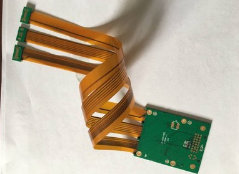

Rigid-flex PCBs, or rigid-flexible printed circuit boards, offer a unique combination of flexibility and durability that make them ideal for use in medical devices.

One of the key benefits of using rigid-flex PCBs in medical devices is their ability to withstand the harsh conditions often found in medical environments.

Medical devices are frequently exposed to moisture, temperature fluctuations, and physical stress, all of which can damage traditional PCBs.

Rigid-flex PCBs, however, are designed to be more resilient, making them better suited for use in medical devices that need to perform reliably in challenging conditions.

In addition to their durability, rigid-flex PCBs also offer a high degree of flexibility, allowing for more compact and lightweight designs.

This flexibility is particularly important in the design of wearable medical devices, such as fitness trackers and medical monitors, where space is limited and comfort is key.

By using rigid-flex PCBs, manufacturers can create devices that are smaller, lighter, and more comfortable for patients to wear.

Furthermore, rigid-flex PCBs offer improved signal integrity and reliability compared to traditional PCBs.

The flexible portions of the PCB can help to reduce signal interference and improve overall performance, making them ideal for use in medical devices that require precise and accurate data transmission.

This is especially important in devices such as pacemakers and defibrillators, where even the smallest signal disruption could have serious consequences.

Another benefit of using rigid-flex PCBs in medical devices is their ability to support complex and intricate designs.

Medical devices are becoming increasingly sophisticated, with more features and functionality packed into smaller and smaller packages.

Rigid-flex PCBs allow for the creation of intricate, multi-layered designs that can accommodate the complex circuitry required for these advanced devices.

Overall, the use of rigid-flex PCBs in medical devices offers a wide range of benefits that can help to improve patient care and outcomes.

From their durability and flexibility to their signal integrity and support for complex designs, rigid-flex PCBs are transforming the way medical devices are designed and manufactured.

As technology continues to advance, we can expect to see even more innovative uses of rigid-flex PCBs in the medical industry, leading to further improvements in patient care and quality of life.

In conclusion, the use of rigid-flex PCBs in medical devices is a game-changer that is helping to drive innovation and improve patient care.

With their unique combination of durability, flexibility, signal integrity, and support for complex designs, rigid-flex PCBs are transforming the way medical devices are designed and manufactured.

As the medical industry continues to evolve, we can expect to see even more advancements in rigid-flex PCB technology that will further enhance the capabilities of medical devices and improve patient outcomes.