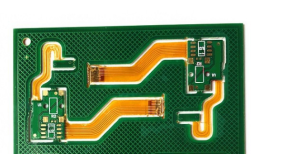

Benefits of Flex Rigid PCB Technology

Flex rigid PCB technology has revolutionized the electronics industry, offering a wide range of benefits that traditional rigid PCBs simply cannot match.

In this article, we will explore the advantages of flex rigid PCB technology and why it is becoming increasingly popular among manufacturers and designers.

One of the key benefits of flex rigid PCB technology is its flexibility. Unlike traditional rigid PCBs, which are made of inflexible materials such as fiberglass, flex rigid PCBs are made of flexible materials that can be bent and twisted without breaking. This flexibility allows for greater design freedom, as designers can create products with unique shapes and configurations that would be impossible with rigid PCBs.

Another major advantage of flex rigid PCB technology is its durability. Flex rigid PCBs are more resistant to shock and vibration than traditional rigid PCBs, making them ideal for use in applications where reliability is critical. This durability also extends the lifespan of the product, reducing the need for frequent repairs and replacements.

Flex rigid PCB technology also offers improved signal integrity. The flexible materials used in flex rigid PCBs help to reduce signal loss and interference, resulting in better performance and reliability. This is especially important in high-speed applications where even small amounts of signal degradation can have a significant impact on performance.

In addition to these benefits, flex rigid PCB technology also offers cost savings. While the initial cost of flex rigid PCBs may be higher than traditional rigid PCBs, the long-term savings can be significant. The durability and reliability of flex rigid PCBs mean that they require less maintenance and replacement, saving manufacturers money in the long run.

Furthermore, flex rigid PCB technology can also help to reduce the overall size and weight of electronic devices. The flexibility of flex rigid PCBs allows for more compact designs, making it possible to create smaller and lighter products without sacrificing performance. This is particularly important in industries such as aerospace and automotive, where weight and space constraints are critical.

Overall, the benefits of flex rigid PCB technology are clear. From improved flexibility and durability to enhanced signal integrity and cost savings, flex rigid PCBs offer a wide range of advantages that make them an attractive choice for manufacturers and designers alike. As technology continues to advance, we can expect to see even more innovations in flex rigid PCB technology that will further enhance its capabilities and benefits.