Benefits of Using Advanced Techniques for Rigid-Flexible PCB Manufacturing and SMT Assembly

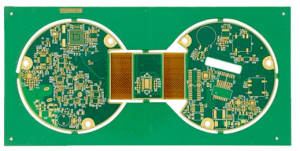

Advanced Techniques for Rigid-Flexible PCB Manufacturing and SMT Assembly

In the world of electronics manufacturing, the demand for smaller, lighter, and more complex devices is constantly increasing.

To meet these demands, manufacturers are turning to advanced techniques for rigid-flexible PCB manufacturing and SMT assembly.

These techniques offer a number of benefits that can help companies stay competitive in today’s fast-paced market.

One of the key benefits of using advanced techniques for rigid-flexible PCB manufacturing is the ability to create more compact and lightweight devices.

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs, allowing for greater design flexibility and reduced space requirements.

This can be particularly useful in applications where space is at a premium, such as in wearable technology or medical devices.

Another benefit of advanced techniques for rigid-flexible PCB manufacturing is improved reliability. Traditional PCBs are prone to failure due to factors such as vibration, thermal expansion, and mechanical stress. Rigid-flex PCBs, on the other hand, are more resistant to these factors, resulting in a more reliable end product. This can be especially important in industries where reliability is critical, such as aerospace or automotive.

In addition to improved reliability, advanced techniques for SMT assembly can also help companies reduce costs and increase efficiency.

By using advanced equipment and processes, manufacturers can achieve higher levels of precision and accuracy, resulting in fewer defects and less rework. This can lead to lower production costs and faster time-to-market, giving companies a competitive edge in today’s fast-paced market.

Furthermore, advanced techniques for SMT assembly can also help companies improve the quality of their products.

By using advanced inspection and testing equipment, manufacturers can identify and correct defects early in the production process,

resulting in higher-quality end products. This can be particularly important in industries where quality is paramount, such as in the medical or defense sectors.

Overall, the benefits of using advanced techniques for rigid-flexible PCB manufacturing and SMT assembly are clear. These techniques offer companies the ability to create more compact and lightweight devices, improve reliability, reduce costs, increase efficiency, and improve product quality. By incorporating these techniques into their manufacturing processes, companies can stay competitive in today’s fast-paced market and meet the growing demand for smaller, lighter, and more complex devices.

In conclusion, advanced techniques for rigid-flexible PCB manufacturing and SMT assembly offer a number of benefits that can help companies stay competitive in today’s fast-paced market. By using these techniques, manufacturers can create more compact and lightweight devices, improve reliability, reduce costs, increase efficiency, and improve product quality. As the demand for smaller, lighter, and more complex devices continues to grow, companies that embrace these advanced techniques will be well-positioned to succeed in the ever-evolving world of electronics manufacturing.