Advanced Rigid-Flex PCBA Techniques for Dense Circuitry in Miniature Drones

In the rapidly evolving world of miniature drone technology, the demand for compact, lightweight, and high-performance printed circuit board assemblies (PCBAs) is ever-increasing.

Miniature drones, also known as micro drones or nano drones, require sophisticated electronic systems to manage their flight controls, sensors, cameras, and communication modules within a limited space.

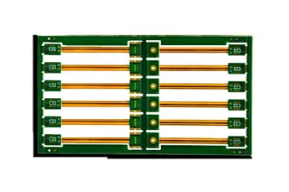

To meet these stringent requirements, manufacturers are turning to advanced rigid-flex PCB assembly techniques that allow for dense circuitry in a flexible and reliable package.

The Evolution of Rigid-Flex PCBA Technology

Over the years, rigid-flex PCBAs have become the go-to solution for many compact electronic devices, including miniature drones.

The combination of rigid and flexible substrates allows for both structural integrity and freedom of design, making them ideal for applications where space is at a premium.

However, as the demand for smaller and more complex drone designs grows, the need for advanced rigid-flex PCBA techniques becomes paramount.

Advanced Routing and Stacking Techniques

One of the key challenges in designing PCBAs for miniature drones is routing the dense circuitry in a way that minimizes signal interference and maintains signal integrity.

Advanced routing techniques, such as differential pair routing and controlled impedance routing, help in optimizing signal paths and reducing cross-talk between traces.

Additionally, stacking multiple layers in a rigid-flex PCBA increases the routing density, allowing for more components to be placed in a smaller space.

Component Miniaturization and Placement Optimization

Miniature drones require components that are not only small in size but also lightweight and power-efficient.

Advanced rigid-flex PCBA techniques involve the use of miniaturized components, such as microcontrollers, sensors, and RF modules, to ensure optimal performance without compromising on size or weight. Furthermore, careful optimization of component placement on the PCB helps in reducing signal delays and improving thermal management, crucial for the reliable operation of miniature drones.

Thermal Management and Material Selection

In dense circuitry applications like miniature drones, thermal management is a critical consideration to prevent overheating and ensure the longevity of electronic components.

Advanced rigid-flex PCBA techniques include the selection of appropriate materials with high thermal conductivity and low thermal resistance to dissipate heat efficiently.

Additionally, the incorporation of heat sinks, thermal vias, and design considerations for airflow within the drone’s enclosure contribute to effective thermal management.

Testing and Quality Assurance

With the intricate nature of advanced rigid-flex PCBAs for miniature drones, thorough testing and quality assurance processes are essential to verify the functionality and reliability of the electronic systems.

Advanced inspection techniques, such as automated optical inspection (AOI) and X-ray inspection, help in detecting defects and ensuring the integrity of solder joints and connections.

Additionally, functional testing under simulated operating conditions guarantees that the drone’s electronic systems perform flawlessly in real-world scenarios.

In conclusion, advanced rigid-flex PCBA techniques play a pivotal role in enabling dense circuitry in miniature drones.

By leveraging cutting-edge routing, stacking, component placement, thermal management, and testing methodologies, manufacturers can design and produce high-performance PCBAs that meet the stringent requirements of modern miniature drone applications.

As the demand for smaller, more agile, and feature-rich drones continues to rise, the adoption of advanced rigid-flex PCBA techniques will be instrumental in shaping the future of drone technology.