Advanced Rigid-Flex PCB Design Techniques for Aerospace and Medical Devices

Advanced rigid-flex PCB design techniques have become increasingly pivotal in the fields of aerospace and medical devices.

As technologies advance, the need for ultra-reliable, compact, and lightweight electronic solutions has led to the adoption of rigid-flex printed circuit boards (PCBs).

These boards are essential for overcoming the engineering challenges associated with high-stakes environments, making their design and implementation critical.

Understanding Rigid-Flex PCBs

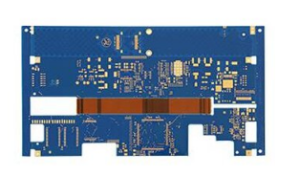

Rigid-flex PCBs combine the attributes of both rigid and flexible circuits into a single board.

This adaptation allows for a more versatile design, facilitating unique configurations that can fit into tight spaces.

Rigid-flex designs provide flexibility in arrangement while maintaining structural integrity, making them ideal for sectors where efficiency and reliability are paramount.

Why Rigid-Flex is Essential for Aerospace and Medical Applications

In aerospace, the weight and space savings provided by rigid-flex PCBs are invaluable.

Aircraft systems demand not just lightweight components but also resilience against vibration, thermal expansion, and extreme environmental conditions.

Similarly, in medical devices, the push for miniaturization is relentless. Devices such as pacemakers and diagnostic equipment benefit from the compactness and reliability that rigid-flex PCBs offer.

Design Techniques for Enhanced Performance

1. Layer Stack-Up Management

One of the most critical aspects of designing rigid-flex PCBs is managing the layer stack-up.

This involves careful selection of materials and thicknesses to achieve the optimal balance between flexibility and rigidity.

Designers often utilize a variety of materials like polyimide and FR-4 to meet specific needs.

The appropriate layer stack-up not only improves electrical performance but also enhances thermal management, which is crucial in both aerospace and medical applications.

2. Minimizing Stress Concentration

When designing rigid-flex PCBs, it is essential to minimize stress concentration points.

These are areas where high mechanical stress can lead to failure, especially in dynamic environments such as aircraft or medical machines that undergo constant movement.

Techniques such as gradual bends instead of sharp corners, maintaining proper spacing, and employing stress-relief features can mitigate potential issues.

3. Utilization of Advanced Simulation Technologies

Leveraging simulation tools during the design phase can significantly enhance the performance of rigid-flex PCBs.

Advanced simulation techniques such as finite element analysis (FEA) allow engineers to visualize how the design will handle thermal and mechanical stresses.

Additionally, electromagnetic simulation can help ensure signal integrity and reduce the risk of electromagnetic interference (EMI), which is particularly critical in medical devices that operate under stringent safety requirements.

Ensuring Reliability through Testing and Prototyping

In sectors like aerospace and medical devices, reliability is non-negotiable. Therefore, rigorous testing and prototyping are integral to the design process.

Accelerated life testing, thermal cycling, and mechanical stress tests help identify potential failure points before the product advances to production.

Creating prototypes allows for iterative design improvements and ensures that the final product meets all industry standards.

Regulatory Considerations

Both the aerospace and medical sectors are governed by strict regulations. Understanding these requirements is critical when designing rigid-flex PCBs.

In medical applications, compliance with the FDA’s regulations for medical devices is essential. For aerospace applications,

following the guidelines set by organizations like the Federal Aviation Administration (FAA) ensures the boards can withstand the demanding conditions encountered in flight.

Future Trends in Rigid-Flex PCB Design

The future of rigid-flex PCBs is ripe with innovation.

With the rise of IoT and increasing demands for smart medical devices, designers will explore new materials and manufacturing processes.

Additionally, the integration of artificial intelligence in design software is likely to streamline the design process, allowing for sophisticated simulations and faster prototyping.

Conclusion

Advanced rigid-flex PCB design techniques are transforming the aerospace and medical industries by offering innovative solutions that meet the relentless demands for performance, reliability, and compactness.

As these technologies evolve, the importance of effective design strategies will only continue to rise.

By embracing these advanced techniques, manufacturers can develop cutting-edge devices that enhance operational capabilities and improve safety in some of the most challenging environments.