Advanced Materials for HDI Rigid-Flex PCBs: Fabricating for 5G and Millimeter-Wave Applications

Advanced materials for HDI (High-Density Interconnect) rigid-flex PCBs are crucial in meeting the ever-increasing demands of modern electronics, particularly in 5G and millimeter-wave applications.

As technology advances, the need for reliable and high-performance printed circuit boards has become paramount.

This article explores the materials that enable the fabrication of innovative HDI rigid-flex PCBs and their significance in supporting high-frequency applications.

Understanding Rigid-Flex PCBs

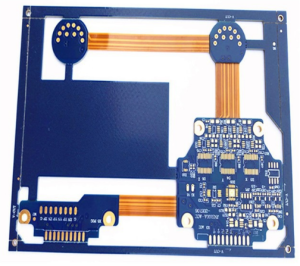

Rigid-flex PCBs combine the attributes of both rigid and flexible circuit boards.

They allow for enhanced design flexibility, reduced assembly time, and improved functionality within compact spaces.

The integration of HDI technology further optimizes these circuits, enabling increased circuit density and opening avenues for advanced electronic configurations.

Importance of 5G in Modern Electronics

The rollout of 5G technology is transforming the landscape of mobile communication.

With its unparalleled speed, lower latency, and improved connectivity, 5G requires PCB solutions that can support the higher frequencies and increased data rates.

HDI rigid-flex PCBs are integral to this transition, providing the necessary design flexibility and robustness for 5G devices and infrastructure.

Key Materials in HDI Rigid-Flex PCB Fabrication

When fabricating HDI rigid-flex PCBs for 5G and millimeter-wave applications, several advanced materials play a vital role:

1. High-Dielectric-Constant Substrates

One of the primary materials used in the fabrication of HDI rigid-flex PCBs is high-dielectric-constant substrates.

These substrates help achieve better impedance control and reduced signal loss at higher frequencies.

Materials such as Rogers’ RO4000 series and Teflon composites are commonly utilized for their excellent dielectric properties and thermal stability.

2. Low-Loss Laminates

To ensure minimal signal degradation, low-loss laminates are essential.

These materials reduce the dielectric loss at high frequencies, making them ideal for applications such as 5G and millimeter-wave circuits.

Companies like Isola and Nelco provide specialized laminate materials designed to optimize performance during high-speed operations.

3. Flexible Copper Foil

The use of flexible copper foils enhances the flexibility and mechanical performance of rigid-flex PCBs.

Ensuring good conductivity while maintaining flexibility is critical.

Advanced manufacturing techniques allow for the production of copper foils with thinner dimensions, which help reduce weight and maintain circuit integrity.

4. Advanced Adhesives

For the lamination process, high-performance adhesives are crucial.

These adhesives must maintain their bond strength and electrical performance under varying conditions, including temperature fluctuations and mechanical stress.

Thermosetting adhesives that provide excellent adhesion and minimal electrical loss are commonly preferred for HDI rigid-flex PCBs.

Manufacturing Techniques for Enhanced Performance

The manufacturing processes for HDI rigid-flex PCBs are continually evolving to meet the demands of advanced applications.

Laser Drilling and Microvia Technology

The emergence of laser drilling technology has revolutionized how microvias are created in HDI boards.

This technique allows for precise hole drilling, which is essential for compact layouts in 5G devices.

Microvias enable multiple layers of circuits in a compact space, making them indispensable for advanced interconnect designs.

Automated Processes

Automation in PCB manufacturing has dramatically improved production efficiency and consistency.

Automated optical inspection (AOI) ensures quality control at every stage, reducing the risk of defects and enhancing reliability in mission-critical applications.

Challenges and Solutions

While the integration of advanced materials presents numerous advantages, it is not without challenges.

For instance, maintaining consistent impedance in multi-layer constructions can be a complex task.

Design simulation tools and specialized manufacturing practices are being employed to address these issues, ensuring performance reliability and adherence to industry standards.

Conclusion

The role of advanced materials in the production of HDI rigid-flex PCBs is pivotal in meeting the challenges posed by 5G and millimeter-wave applications.

As connectivity continues to evolve, the demand for high-performance circuit boards will only grow.

By leveraging innovative materials and manufacturing techniques, the electronics industry can produce efficient, reliable, and compact circuit solutions that will power the next generation of technology.

The fusion of rigid and flexible technologies, exemplified by HDI rigid-flex PCBs, ensures that the future of electronic circuitry remains bright and full of potential.