Implementing Embedded Components for Increased Component Density

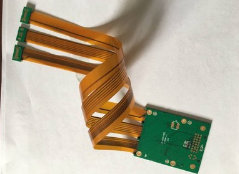

In the ever-evolving world of printed circuit board (PCB) design, the demand for high-density rigid-flex PCBs continues to grow.

As technology advances, electronic devices are becoming smaller and more complex, requiring designers to find innovative ways to increase component density while maintaining reliability and performance.

One advanced design technique that is gaining popularity is the use of embedded components.

Embedded components involve placing passive or active components within the layers of the PCB, rather than on the surface.

This technique allows for a significant increase in component density, as components can be placed closer together without sacrificing board space.

By embedding components, designers can achieve a more compact and lightweight PCB design, making it ideal for applications where space is limited.

One of the key benefits of embedded components is the reduction of signal interference and noise.

Placing components within the PCB layers helps to shield them from external electromagnetic interference, resulting in improved signal integrity and reliability.

This is especially important in high-frequency applications where signal quality is critical.

Another advantage of embedded components is the improved thermal performance of the PCB.

By embedding components within the layers, heat dissipation is more efficient, as the components are in direct contact with the copper traces and ground planes.

This helps to prevent overheating and ensures the longevity of the components.

Implementing embedded components in high-density rigid-flex PCBs requires careful planning and consideration.

Designers must take into account factors such as component placement, routing, and manufacturing processes to ensure a successful implementation.

Advanced design tools and simulation software can help designers optimize the placement of embedded components and analyze their impact on the overall performance of the PCB.

When designing a PCB with embedded components, it is important to work closely with the PCB manufacturer to ensure that the design can be successfully manufactured.

Specialized manufacturing processes, such as laser drilling and controlled impedance routing, may be required to create the necessary vias and traces for embedding components.

Collaboration with the manufacturer early in the design process can help to identify any potential manufacturing challenges and ensure a smooth production process.

As technology continues to advance, the demand for high-density rigid-flex PCBs with embedded components is expected to increase.

Designers who embrace this advanced design technique will be able to create more compact and reliable PCB designs that meet the evolving needs of the electronics industry.

By implementing embedded components, designers can achieve higher component density, improved signal integrity, and enhanced thermal performance, making it a valuable technique for high-density rigid-flex PCBs in 2025 and beyond.