Benefits of Using Flex PCBs in Electronic Devices

Flex PCBs, or flexible printed circuit boards, have become increasingly popular in the electronics industry due to their numerous benefits. These flexible circuit boards offer a wide range of advantages over traditional rigid PCBs, making them an ideal choice for many electronic devices. In this article, we will explore the benefits of using flex PCBs in electronic devices.

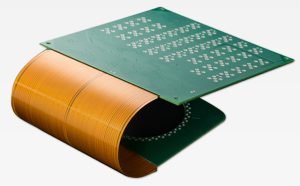

One of the key advantages of flex PCBs is their flexibility and durability. Unlike rigid PCBs, which are made of inflexible materials such as fiberglass, flex PCBs are made of flexible materials such as polyimide or polyester. This flexibility allows them to be bent, twisted, and folded without breaking, making them ideal for use in devices that require a high degree of flexibility.

In addition to their flexibility, flex PCBs are also more durable than rigid PCBs. The flexible materials used in flex PCBs are able to withstand a greater degree of bending and twisting without sustaining damage, making them ideal for use in devices that are subject to frequent movement or vibration. This increased durability can help to extend the lifespan of electronic devices and reduce the need for frequent repairs or replacements.

Another benefit of using flex PCBs in electronic devices is their compact size and lightweight design. Flex PCBs are thinner and lighter than rigid PCBs, allowing for more compact and lightweight electronic devices. This can be particularly advantageous in devices where space is limited or weight is a concern, such as wearable technology or portable electronics.

Flex PCBs also offer greater design flexibility than rigid PCBs. The flexible nature of flex PCBs allows for more complex and intricate designs, making it easier to incorporate features such as curved or irregular shapes, multiple layers, and tight spaces. This increased design flexibility can help to improve the performance and functionality of electronic devices, as well as reduce the overall size and weight of the device.

In addition to their physical advantages, flex PCBs also offer a number of practical benefits. For example, flex PCBs are easier and more cost-effective to manufacture than rigid PCBs. The flexible materials used in flex PCBs can be easily cut, shaped, and assembled, reducing the time and cost of production. This can help to lower the overall cost of electronic devices and make them more affordable for consumers.

Flex PCBs are also more reliable than rigid PCBs. The flexible materials used in flex PCBs are less prone to cracking, delamination, and other forms of damage that can occur with rigid PCBs. This increased reliability can help to improve the performance and longevity of electronic devices, as well as reduce the risk of malfunctions or failures.

Overall, the benefits of using flex PCBs in electronic devices are clear. From their flexibility and durability to their compact size and lightweight design, flex PCBs offer a wide range of advantages over traditional rigid PCBs. With their increased design flexibility, ease of manufacture, and reliability, flex PCBs are an ideal choice for many electronic devices.