The design and manufacturing of rigid-flex PCBs offer numerous advantages, such as space savings, improved reliability, and enhanced design flexibility.

However, the process can be costly, especially when considering the complexity of the design, materials, and fabrication techniques involved.

As technology continues to advance, finding ways to minimize rigid-flex PCB design costs without compromising quality is crucial for businesses seeking to stay competitive in the electronics industry.

In this article, we will explore effective strategies and tips on how to reduce rigid-flex PCB design costs without sacrificing quality.

Understanding Rigid-Flex PCB Design Costs

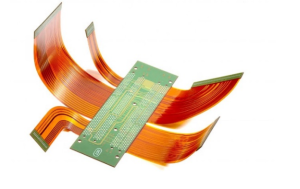

Rigid-flex PCBs combine elements of both rigid and flexible PCBs, offering a versatile solution for complex electronic device designs.

The unique construction of rigid-flex PCBs allows for greater freedom in creating compact and durable electronic assemblies.

However, the intricate design and manufacturing processes of rigid-flex PCBs can drive up the overall production costs.

Design Efficiency and Optimization

One of the key areas where costs can be reduced in rigid-flex PCB design is through efficient design practices.

By optimizing the layout and minimizing the number of layers required, designers can eliminate unnecessary complexity and reduce material usage.

Utilizing design software that offers features like design rule checking (DRC) and design for manufacturability (DFM) can help identify potential issues early on in the design phase, avoiding costly revisions later in the process.

Material Selection and Cost-Effective Alternatives

Choosing the right materials for a rigid-flex PCB design is crucial for achieving the desired performance and reliability.

While high-performance materials may offer superior electrical and mechanical properties, they often come at a premium cost.

Conducting a thorough analysis of material requirements and considering cost-effective alternatives can help lower overall material expenses without compromising quality.

Partnership with Experienced Suppliers and Manufacturers

Collaborating with experienced suppliers and manufacturers is essential for cost-effective rigid-flex PCB production.

Established partners can provide valuable insights into cost-saving opportunities, such as bulk purchasing discounts, alternative material options, and efficient manufacturing processes.

By building strong relationships with trusted suppliers, businesses can negotiate favorable pricing terms and streamline the procurement process.

Design for Manufacturability (DFM) Guidelines

Designing with manufacturing processes in mind is critical for reducing costs in rigid-flex PCB production.

Following design for manufacturability (DFM) guidelines can help minimize errors, optimize assembly processes, and improve overall manufacturability.

By designing with DFM principles, designers can reduce the risk of costly rework, shorten production lead times, and enhance the overall quality of the final product.

Streamlined Prototyping and Testing Processes

Efficient prototyping and testing processes are essential for cost-effective rigid-flex PCB design.

By streamlining the prototyping phase and conducting thorough testing early in the design cycle, potential issues can be identified and addressed promptly, reducing the risk of costly design revisions later on.

Investing in advanced prototyping technologies, such as rapid PCB prototyping services, can help accelerate the product development cycle and minimize time-to-market.

Conclusion

In conclusion, reducing rigid-flex PCB design costs without sacrificing quality requires a strategic approach that encompasses design efficiency, material optimization, supplier partnerships, DFM guidelines, and streamlined prototyping processes. By implementing these cost-effective strategies and best practices, businesses can achieve significant cost savings while delivering high-quality rigid-flex PCBs that meet the demands of modern electronics applications.

Effective cost management in rigid-flex PCB design is essential for staying competitive in the rapidly evolving electronics industry.

By focusing on efficient design practices, material optimization, strategic partnerships, and streamlined manufacturing processes, businesses can successfully reduce costs without compromising the quality and performance of their rigid-flex PCB designs.