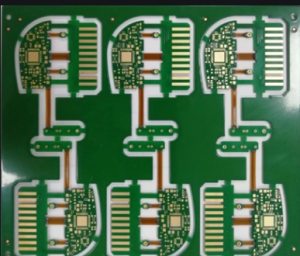

Rigid-Flex PCB designs have gained considerable popularity in the electronics industry due to their ability to address various design challenges, offer flexibility, and optimize space utilization.

However, one crucial aspect that often concerns engineers and manufacturers is the cost associated with designing and manufacturing Rigid-Flex PCBs.

In this article, we will delve into the key factors that influence Rigid-Flex PCB design costs and provide a detailed breakdown to help you better understand the pricing structure.

Factors Influencing Rigid-Flex PCB Design Costs

Material Selection

The choice of materials plays a significant role in determining the overall cost of Rigid-Flex PCB designs.

High-quality and specialized materials, such as polyimide films and flexible substrates, can be more expensive than traditional rigid PCB materials.

Additionally, factors like material thickness and copper weight can also impact the cost.

Complexity of Design

The complexity of the Rigid-Flex PCB design directly affects the cost involved in its fabrication.

Intricate designs with multiple layers, tight tolerances, and complex geometries require more precise manufacturing processes and advanced equipment, leading to higher costs.

Quantity

The volume of Rigid-Flex PCBs ordered is a key determinant of the overall cost per unit.

Economies of scale come into play here, with larger production runs typically resulting in lower costs per board.

Ordering small quantities may incur higher costs due to setup expenses and manufacturing overheads.

Technology and Manufacturing Processes

The use of innovative technologies and advanced manufacturing processes can contribute to increased costs but also offer enhanced performance and reliability.

Factors like HDI (High-Density Interconnect) technology, laser drilling, and impedance control can add to the overall price of Rigid-Flex PCB production.

Testing and Quality Assurance

Investing in thorough testing and quality assurance measures is essential to ensure the functionality and reliability of Rigid-Flex PCBs.

Testing processes, such as electrical testing, impedance testing, and reliability testing, incur additional costs but are crucial for detecting and rectifying any defects early in the production cycle.

Supplier and Location

The choice of PCB manufacturer and their location can impact the overall cost of Rigid-Flex PCB design.

Offshore suppliers may offer lower labor costs, but factors like shipping expenses, lead times, and quality control measures must be considered when selecting a manufacturing partner.

Breakdown of Rigid-Flex PCB Design Costs

When breaking down the costs associated with Rigid-Flex PCB design, it is essential to consider the following components:

- Materials Cost: This includes the cost of all materials used in the fabrication of the Rigid-Flex PCB, such as substrates, copper foils, adhesives, and protective coatings.

- Labor Costs: Labor costs encompass the expenses related to design engineering, manufacturing, assembly, testing, and quality control processes involved in producing Rigid-Flex PCBs.

- Equipment and Tooling Costs: Investment in specialized equipment, tools, and machinery required for Rigid-Flex PCB fabrication adds to the overall production costs.

- Overhead Costs: Overhead costs cover expenses like facility maintenance, utilities, administrative expenses, and overheads associated with running a PCB manufacturing facility.

- Quality Assurance and Testing Costs: Quality assurance measures, testing equipment, and procedures contribute to the overall cost but are crucial for ensuring product reliability and performance.

By understanding the key factors influencing Rigid-Flex PCB design costs and breaking down the cost components, engineers and manufacturers can make informed decisions to optimize design efficiency and cost-effectiveness. Proper planning, material selection, design simplification, and strategic partnerships with reliable suppliers can help mitigate costs while ensuring the desired functionality and quality of Rigid-Flex PCBs.