Exploring the World of Ruggedized Rigid-Flex PCBs for Outdoor and Adventure Wearables

In the realm of wearable technology, where durability and flexibility are crucial, the emergence of ruggedized rigid-flex PCBs has paved the way for innovative solutions in outdoor and adventure wearables.

Designed to withstand harsh environments and extreme conditions, these specialized circuit boards offer a unique blend of toughness and adaptability that is ideal for consumer electronics built for exploration and adventure.

What are Ruggedized Rigid-Flex PCBs?

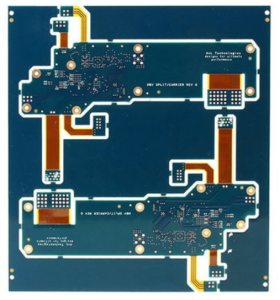

Ruggedized rigid-flex PCBs represent a cutting-edge solution in the world of printed circuit boards.

Combining the durability of rigid boards with the flexibility of flexible circuits, these specialized PCBs are built to endure challenging conditions such as moisture, temperature variations, mechanical stress, and vibrations.

This makes them an ideal choice for outdoor and adventure wearables, where traditional PCBs may not stand up to the rigors of active lifestyles.

Benefits of Ruggedized Rigid-Flex PCBs for Wearables

One of the key advantages of using ruggedized rigid-flex PCBs in outdoor and adventure wearables is their ability to withstand physical stress without compromising performance.

Whether it’s a rugged smartwatch for hikers or a durable fitness tracker for athletes, these specialized PCBs ensure reliability in the face of demanding environments.

The flexibility of rigid-flex PCBs also allows for innovative designs that can conform to the shape of the wearable device, maximizing space utilization and enhancing overall functionality.

Applications in Outdoor and Adventure Wearables

The applications of ruggedized rigid-flex PCBs in outdoor and adventure wearables are diverse and far-reaching.

From GPS trackers and fitness monitors to action cameras and smart eyewear, these specialized circuit boards enable the development of next-generation wearable devices that can keep up with the active lifestyles of consumers. Manufacturers are increasingly turning to ruggedized rigid-flex PCBs to create products that can withstand the challenges of outdoor activities such as hiking, biking, skiing, and rock climbing.

Design Considerations and Manufacturing Challenges

Designing and manufacturing ruggedized rigid-flex PCBs for outdoor and adventure wearables come with their own set of challenges.

Ensuring that the circuit boards are both durable and flexible requires careful planning and meticulous attention to detail.

Factors such as material selection, layer configuration, routing constraints, and testing procedures play a critical role in producing high-quality PCBs that can withstand the demands of outdoor environments.

Collaboration between design engineers, PCB manufacturers, and wearable device developers is essential to address these challenges and create robust solutions that meet the unique requirements of outdoor and adventure wearables.

The Future of Ruggedized Rigid-Flex PCBs in Wearable Technology

As the demand for outdoor and adventure wearables continues to grow, the role of ruggedized rigid-flex PCBs in shaping the future of wearable technology is becoming increasingly significant.

Advancements in materials, manufacturing processes, and design techniques are driving innovation in the development of durable and flexible circuit boards that can meet the evolving needs of consumers.

With continued research and development, we can expect to see more sophisticated and reliable ruggedized rigid-flex PCBs powering the next generation of outdoor and adventure wearables, providing users with enhanced performance, durability, and functionality in their active pursuits.

In conclusion, ruggedized rigid-flex PCBs are revolutionizing the world of outdoor and adventure wearables by offering a unique combination of durability, flexibility, and performance.

These specialized circuit boards are enabling the creation of innovative wearable devices that can withstand the challenges of active lifestyles, opening up new possibilities for exploration and adventure.

As technology continues to evolve, ruggedized rigid-flex PCBs will play a key role in shaping the future of wearable technology, empowering users to push the boundaries of what is possible in their outdoor pursuits.