Innovative Rigid-Flex PCB Assembly for Seamless Integration in Smart Furniture and Surfaces

Rigid-flex PCB assembly is revolutionizing the integration of electronic components in smart furniture and surfaces.

As technology advances and the demand for smart solutions grows, the need for flexible and versatile circuit board designs has become crucial.

Rigid-flex PCBs offer a distinctive solution to the challenges posed by the integration of electronics into curved or non-standard form factors, enabling seamless and efficient designs for a wide range of applications.

What is Rigid-Flex PCB Assembly?

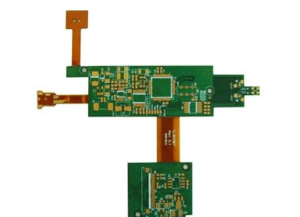

Rigid-flex PCB assembly involves combining rigid and flexible circuit board materials into a single unit, providing enhanced durability, flexibility, and space efficiency.

The rigid portions of the PCB provide structural support and house components that require stability, while the flexible sections enable the board to bend or conform to the shape of the surface it is mounted on.

This unique construction allows for intricate designs that can adapt to the contours of smart furniture, curved surfaces, or wearable devices.

Key Benefits of Rigid-Flex PCB Assembly

Space Efficiency: Rigid-flex PCBs eliminate the need for bulky connectors and cables, reducing the overall footprint of the electronic system.

This space-saving feature is especially valuable in smart furniture and surfaces where slim and seamless integration is desired.

Enhanced Reliability: The elimination of interconnects and solder joints in rigid-flex PCB assembly reduces the risk of potential failure points, enhancing the overall reliability of the electronic system.

This is essential for applications where continuous operation is vital.

Improved Design Flexibility: Rigid-flex PCBs offer unparalleled design flexibility, allowing engineers to create customized layouts that meet the specific requirements of smart furniture and surfaces.

The ability to bend, twist, and shape the PCB enables innovative and ergonomic designs that were previously unattainable.

Applications of Rigid-Flex PCB Assembly in Smart Furniture and Surfaces

Smart Lighting Systems: Rigid-flex PCBs are ideal for integrating LED lighting systems into furniture and surfaces, providing a seamless and aesthetically pleasing lighting solution.

The flexible nature of the PCB allows for the creation of intricate lighting patterns and designs.

Touch-sensitive Surfaces: Rigid-flex PCB assembly can be used to create touch-sensitive surfaces in furniture, countertops, or walls.

These interactive surfaces can be integrated with sensors and control panels to enable intuitive user interactions.

Embedded Electronics: Rigid-flex PCBs enable the seamless integration of electronic components such as sensors, actuators, and controllers into smart furniture and surfaces.

This integration enhances the functionality and connectivity of the furniture, enabling features such as IoT connectivity and smart automation.

Future Trends in Rigid-Flex PCB Assembly

As the demand for smart solutions continues to grow, the adoption of rigid-flex PCB assembly in smart furniture and surfaces is expected to increase significantly.

Advancements in materials, manufacturing processes, and design tools will further enhance the capabilities of rigid-flex PCBs, enabling more complex and integrated electronic systems.

In conclusion, rigid-flex PCB assembly offers a groundbreaking solution for the seamless integration of electronic components in smart furniture and surfaces.

With their space efficiency, reliability, and design flexibility, rigid-flex PCBs are poised to drive innovation and creativity in the field of smart technology.

As the industry continues to evolve, the use of rigid-flex PCBs is expected to play a pivotal role in shaping the future of electronic integration in smart environments.