Rethinking Electronics: Sustainable Materials in Rigid-Flex PCB Manufacturing for Eco-Conscious IoT Devices

The rise of the Internet of Things (IoT) has brought about a rapid proliferation of interconnected devices, revolutionizing the way we interact with technology.

As the demand for IoT devices continues to soar, the importance of sustainability in their manufacturing processes cannot be overstated.

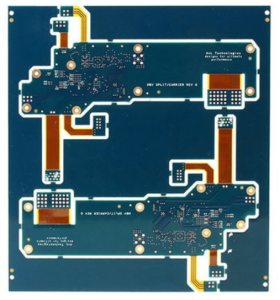

One key area of focus is the use of sustainable materials in the production of rigid-flex printed circuit boards (PCBs), which are essential components in many IoT devices.

By incorporating eco-friendly materials into the manufacturing of rigid-flex PCBs, companies can reduce their environmental footprint and contribute to a more sustainable future.

The Importance of Sustainable Materials in Rigid-Flex PCB Manufacturing

Rigid-flex PCBs are gaining popularity for their ability to combine the durability of rigid boards with the flexibility of flex circuits.

These PCBs are essential in IoT devices, as they provide the necessary electrical connections in a compact and reliable manner.

However, the conventional manufacturing processes of rigid-flex PCBs often rely on materials that are harmful to the environment, such as lead-based solders and non-recyclable substrates.

Advancements in Sustainable Materials

In recent years, significant advancements have been made in the development of sustainable materials for use in rigid-flex PCB manufacturing.

One key area of focus is the use of recycled materials, such as recycled copper and substrate materials.

By incorporating recycled materials into the manufacturing process, companies can significantly reduce their environmental impact and decrease the demand for virgin resources.

Furthermore, the use of biodegradable or compostable materials in rigid-flex PCB manufacturing is gaining traction.

These materials break down naturally over time, reducing the amount of waste generated by electronics manufacturing processes.

By choosing biodegradable materials for rigid-flex PCBs, companies can align their manufacturing processes with environmental principles and reduce their overall carbon footprint.

Exploring Renewable Energy Sources for Manufacturing Processes

Another crucial aspect of sustainability in rigid-flex PCB manufacturing is the integration of renewable energy sources into the production processes.

By utilizing solar, wind, or other renewable energy sources to power manufacturing facilities, companies can significantly reduce their carbon emissions and reliance on non-renewable energy sources.

Regulatory Compliance and Certification

Ensuring that rigid-flex PCBs are manufactured using sustainable materials requires compliance with environmental regulations and certifications.

Companies can obtain certifications such as the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of hazardous materials in electronic products.

By adhering to regulatory standards and obtaining certifications, companies can demonstrate their commitment to sustainability and environmental stewardship.

Conclusion

In conclusion, the incorporation of sustainable materials in rigid-flex PCB manufacturing is crucial for the development of eco-conscious IoT devices.

By leveraging recycled materials, biodegradable substrates, and renewable energy sources, companies can reduce their environmental impact and contribute to a more sustainable future.

As the demand for IoT devices continues to grow, it is imperative that manufacturers prioritize sustainability in their production processes to ensure a greener and more environmentally friendly electronics industry.